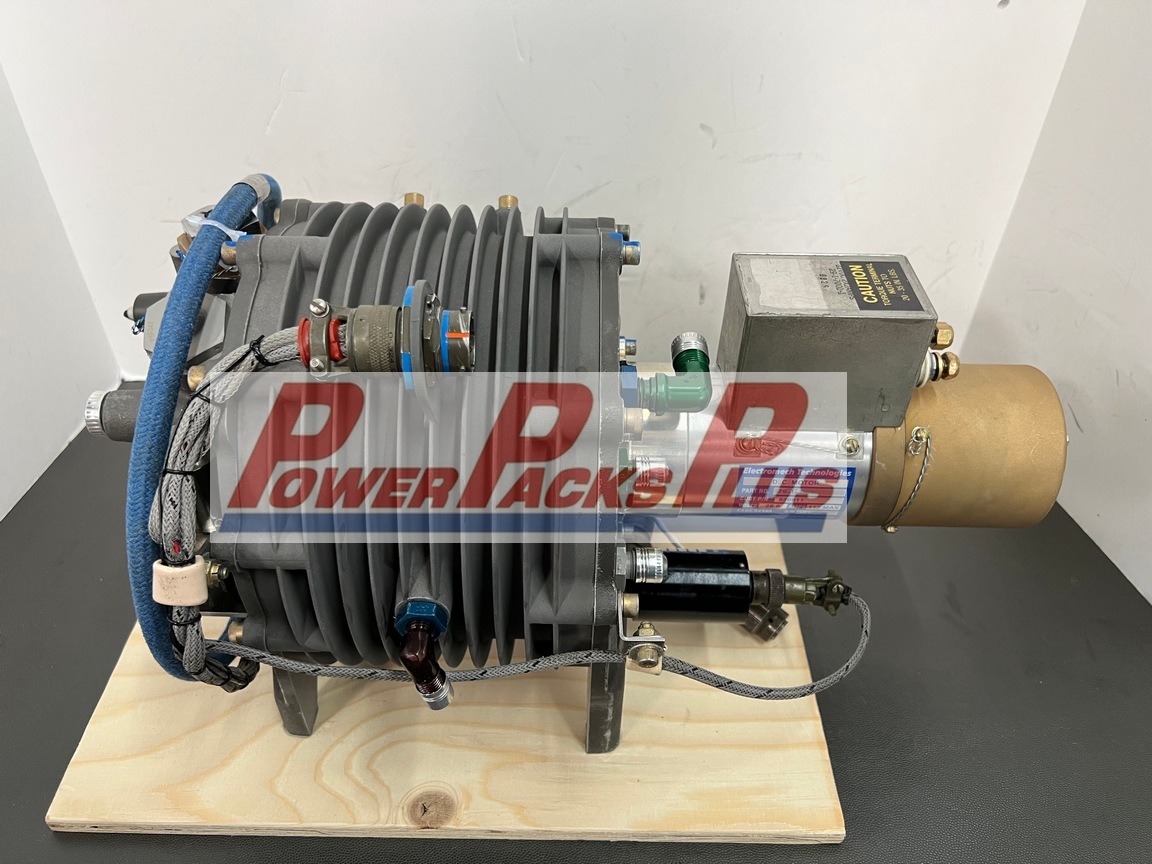

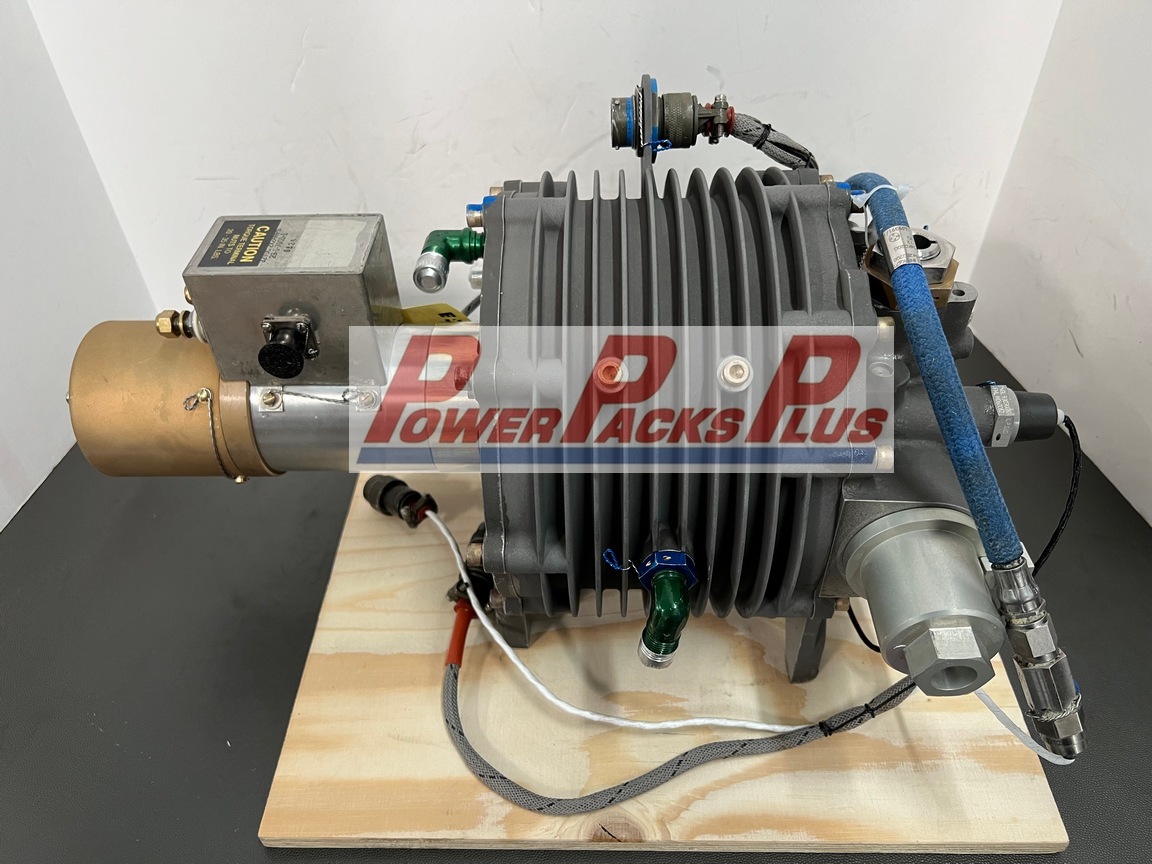

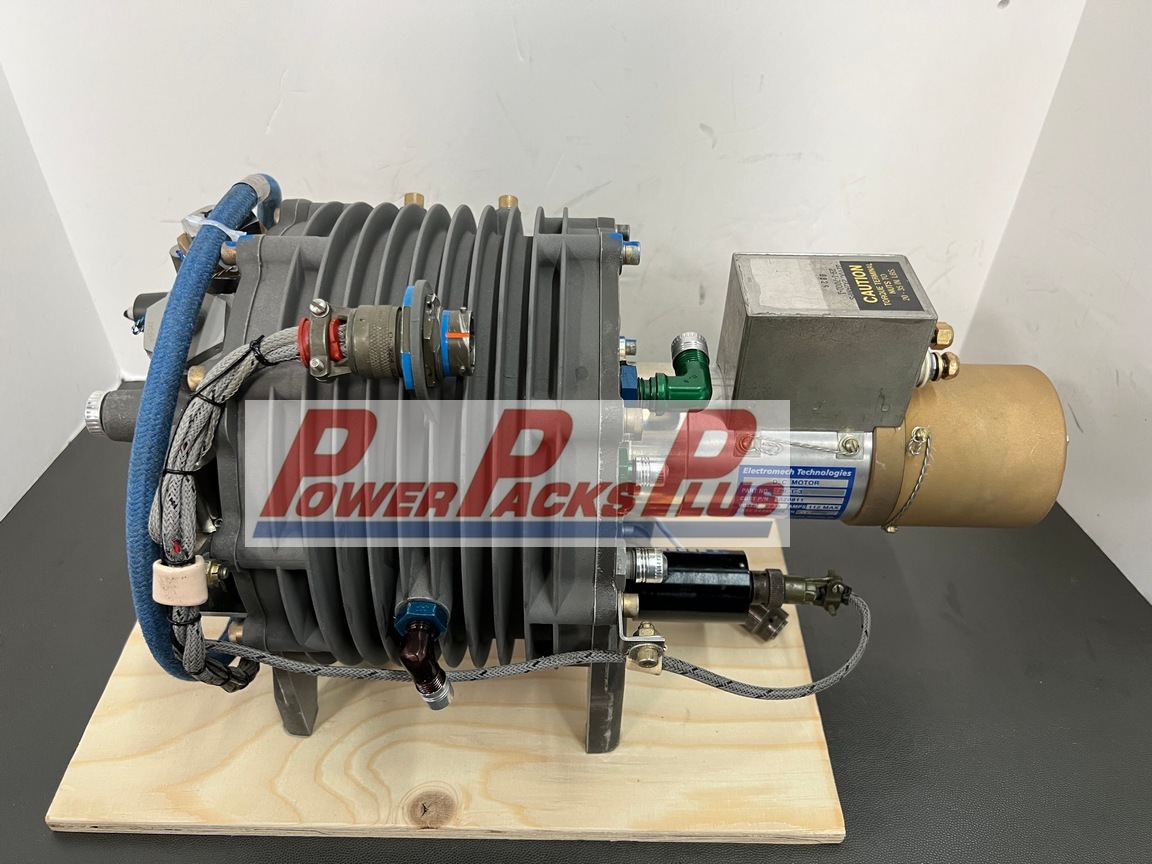

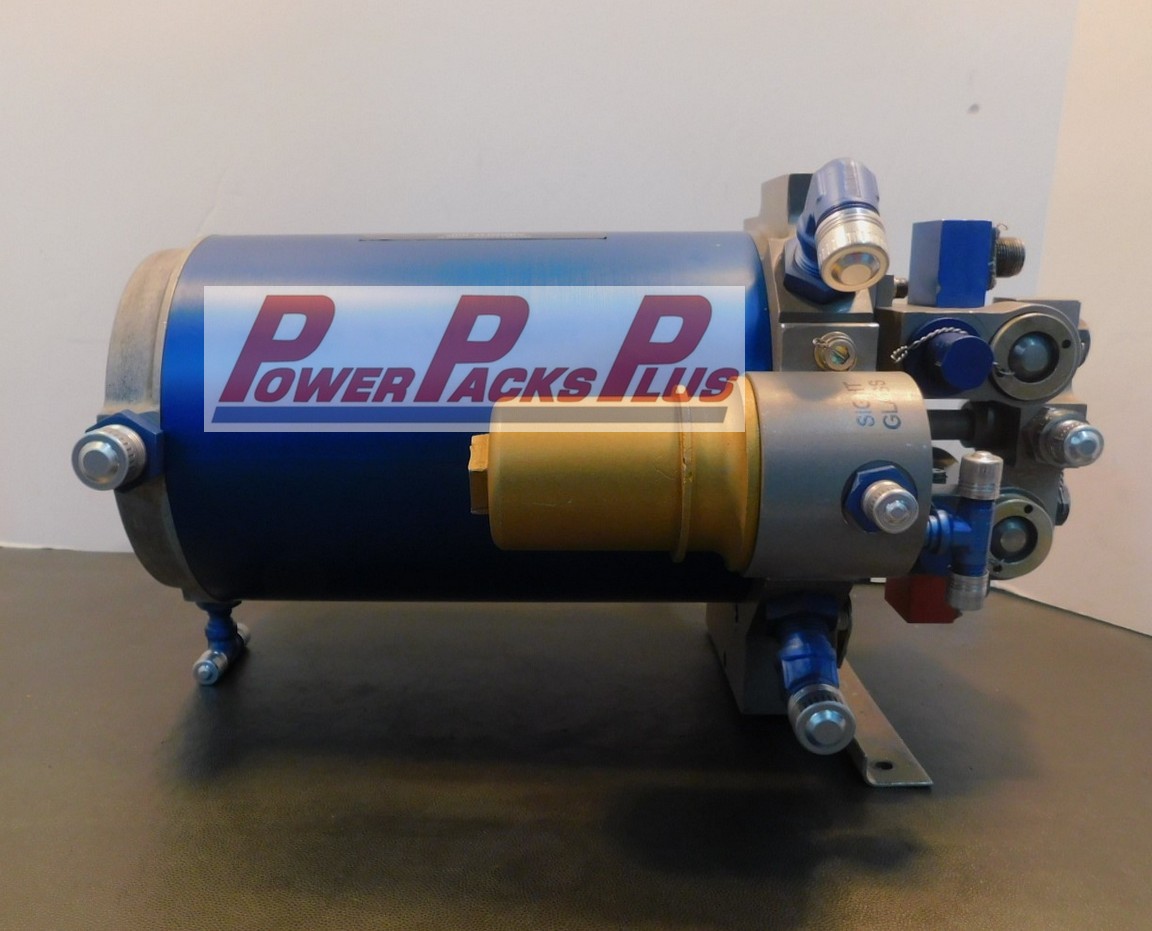

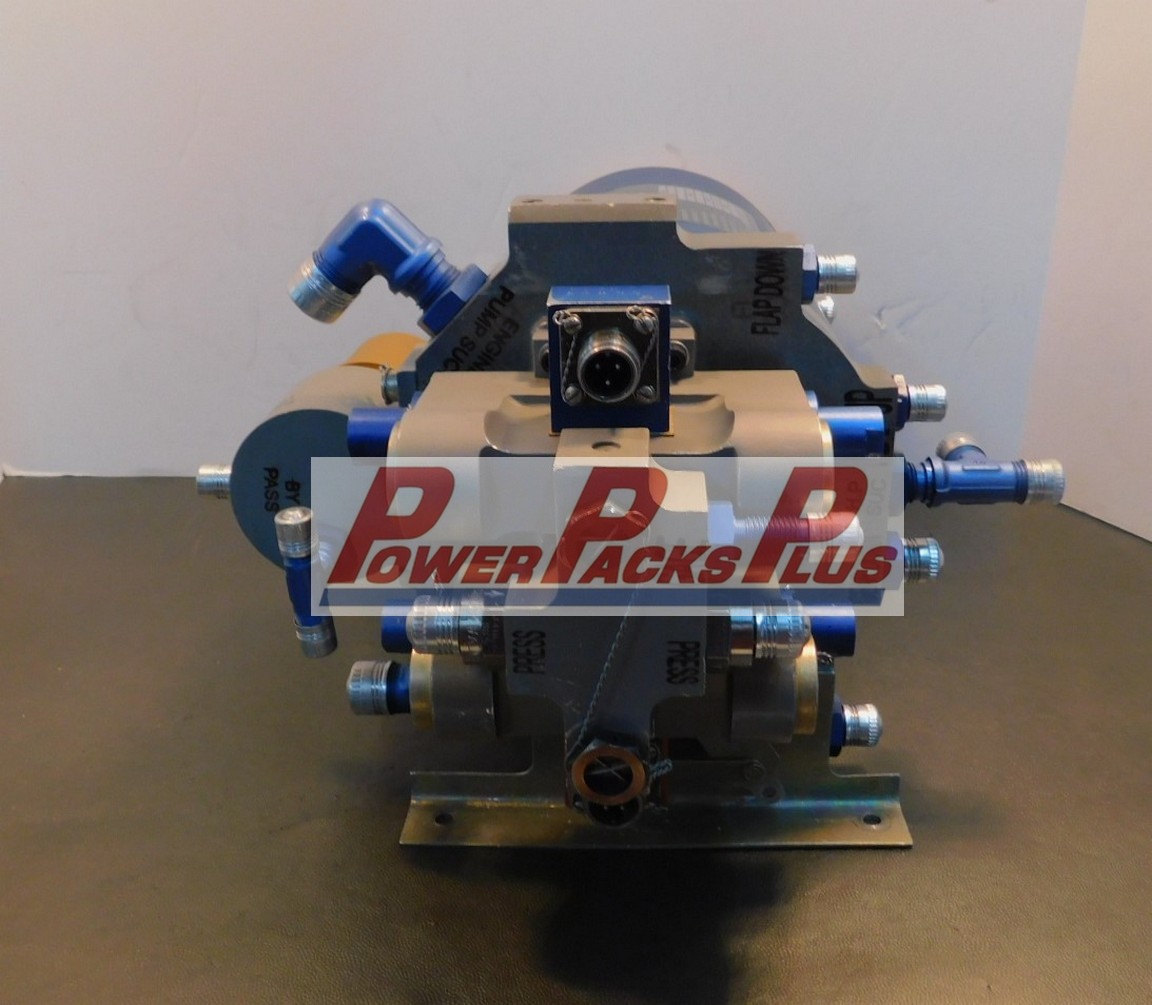

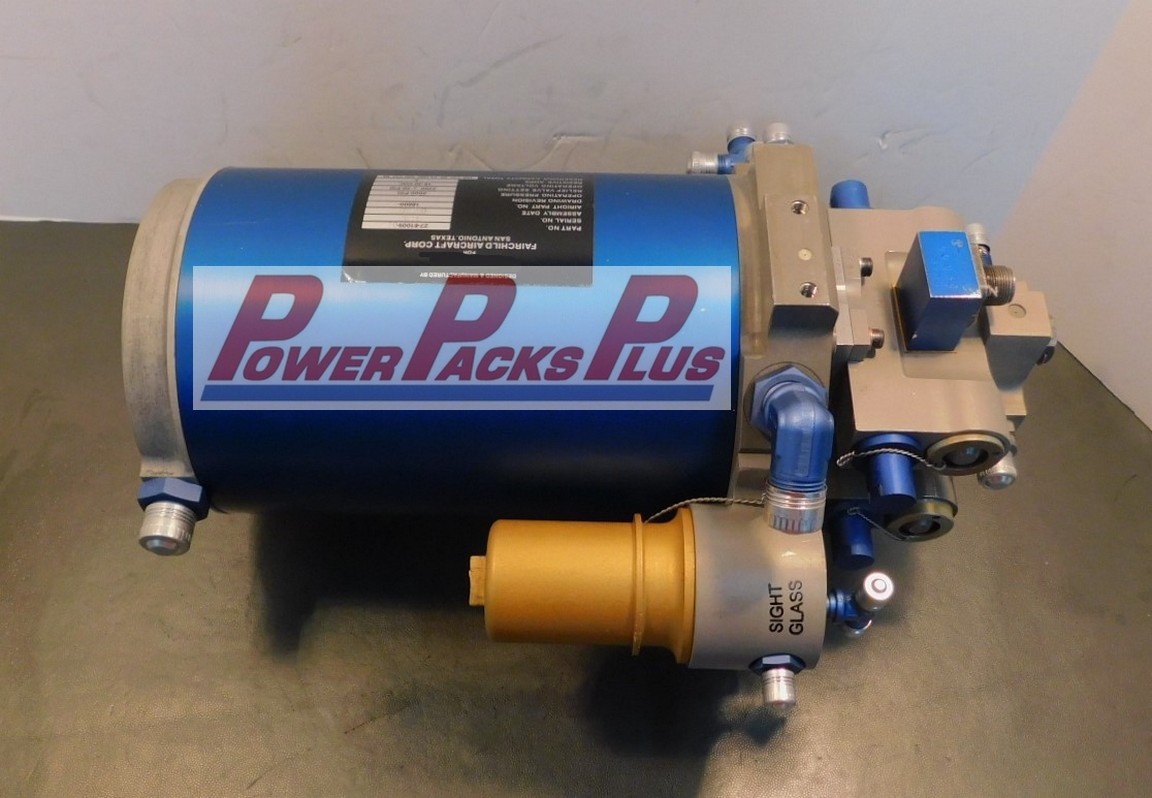

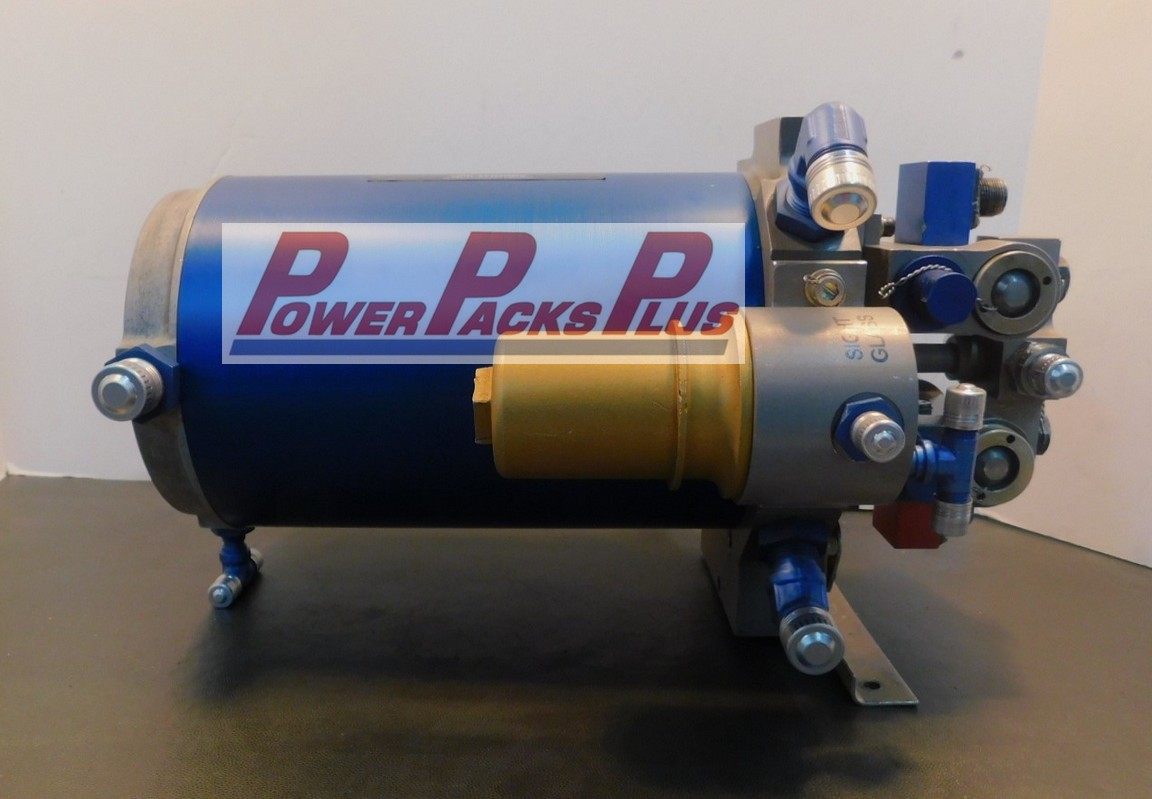

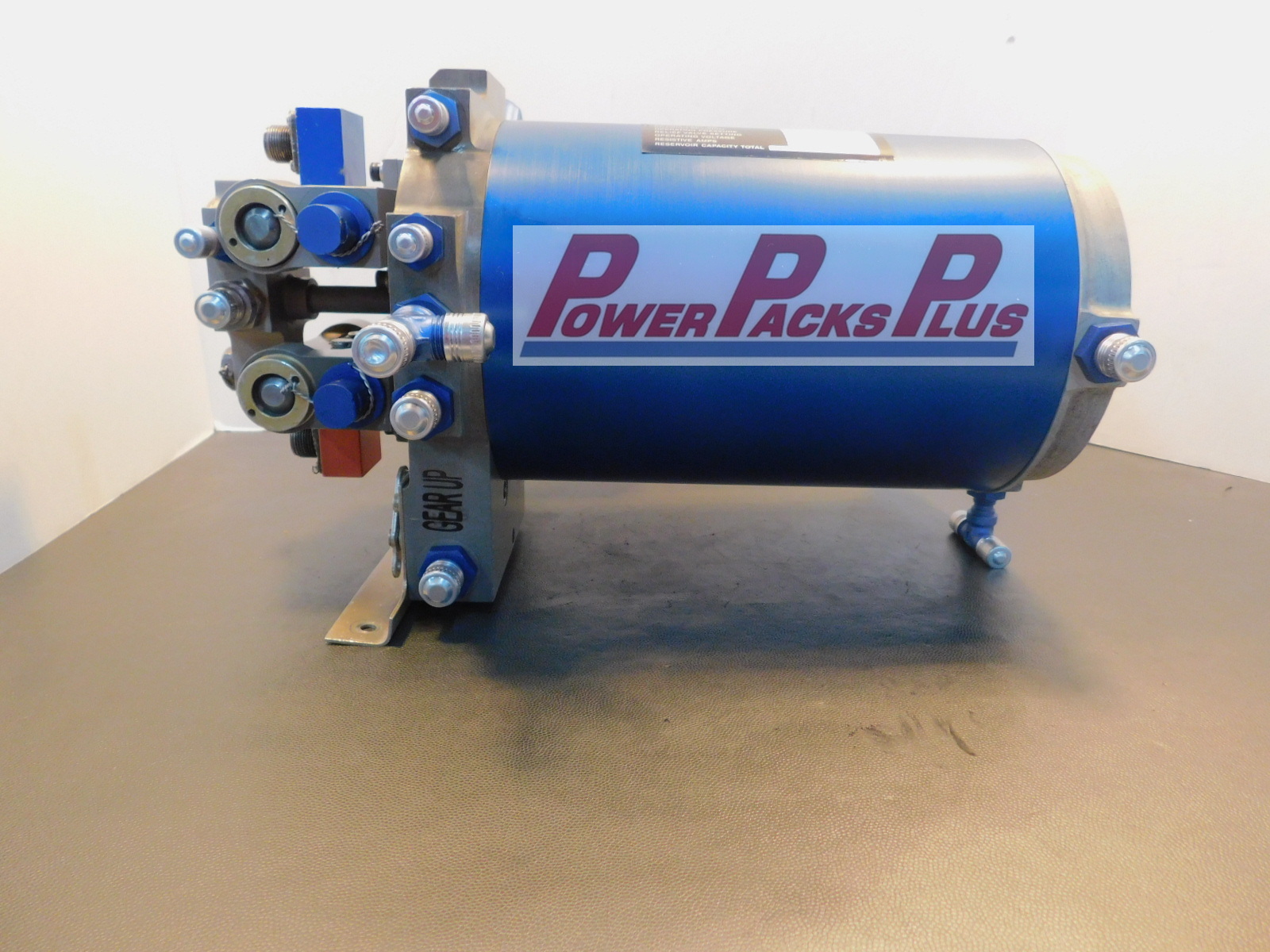

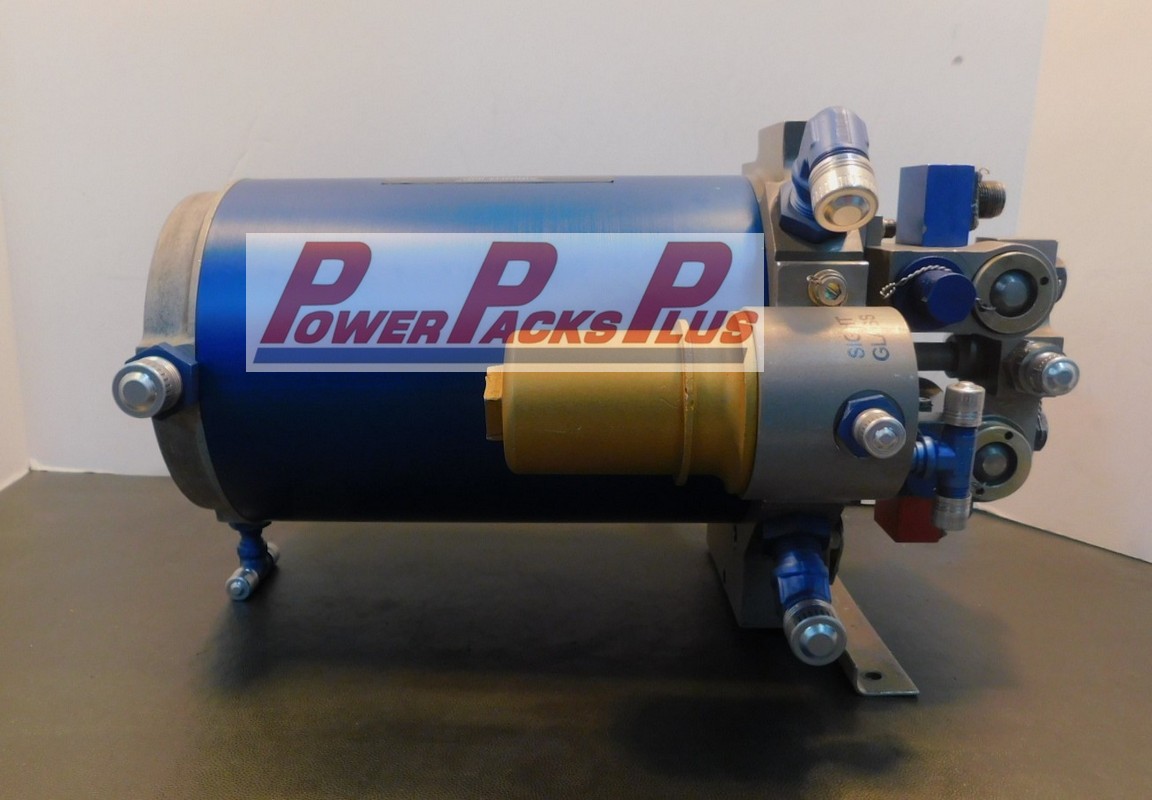

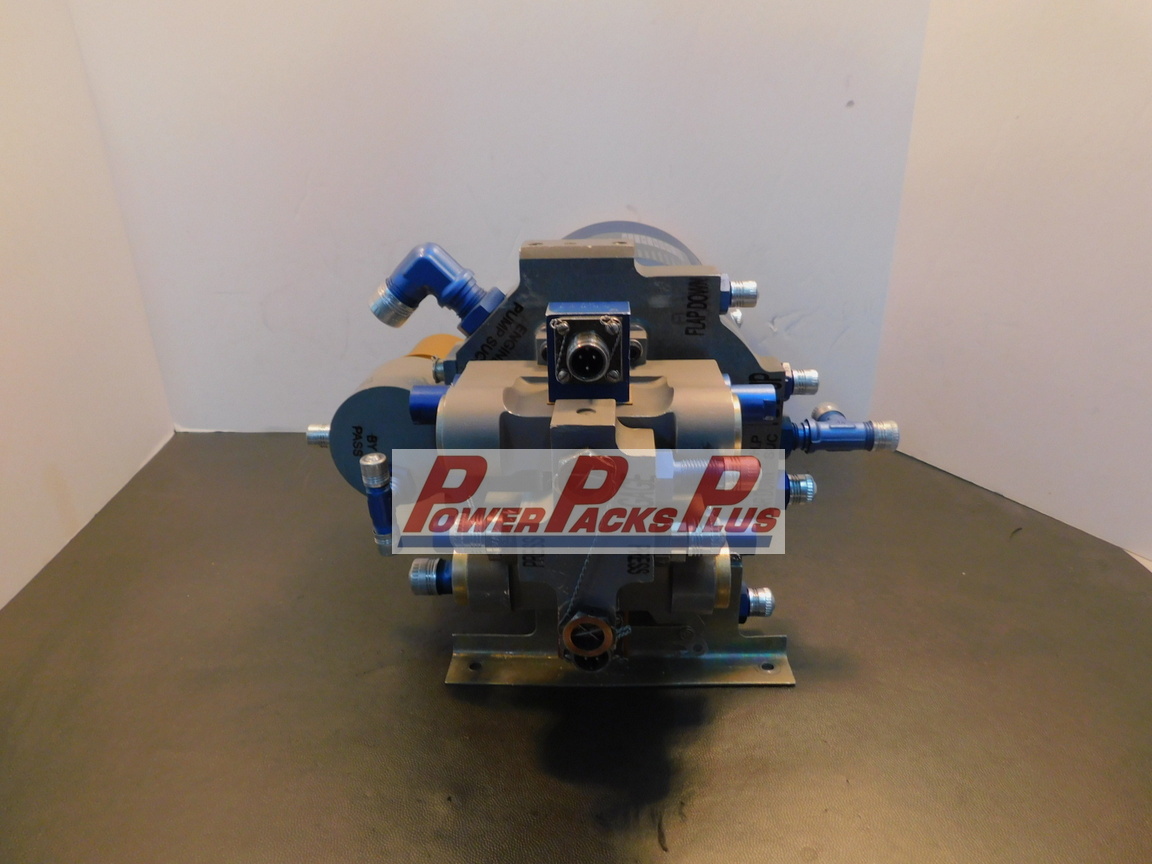

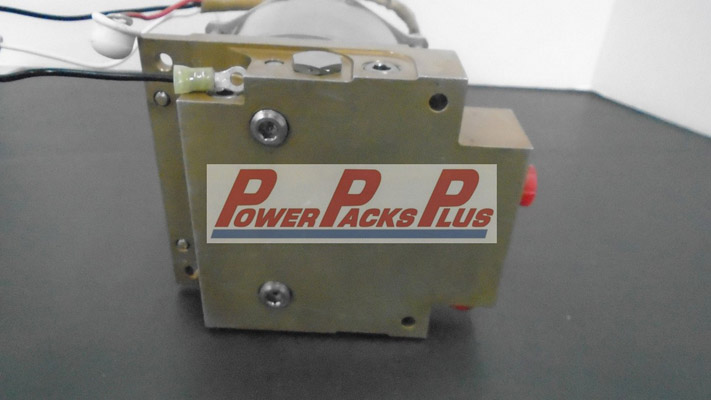

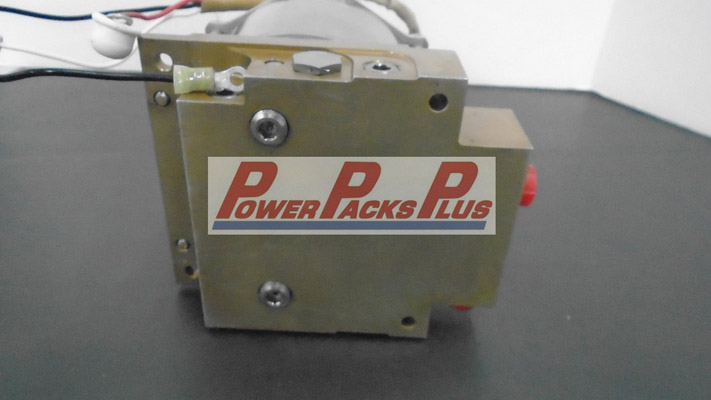

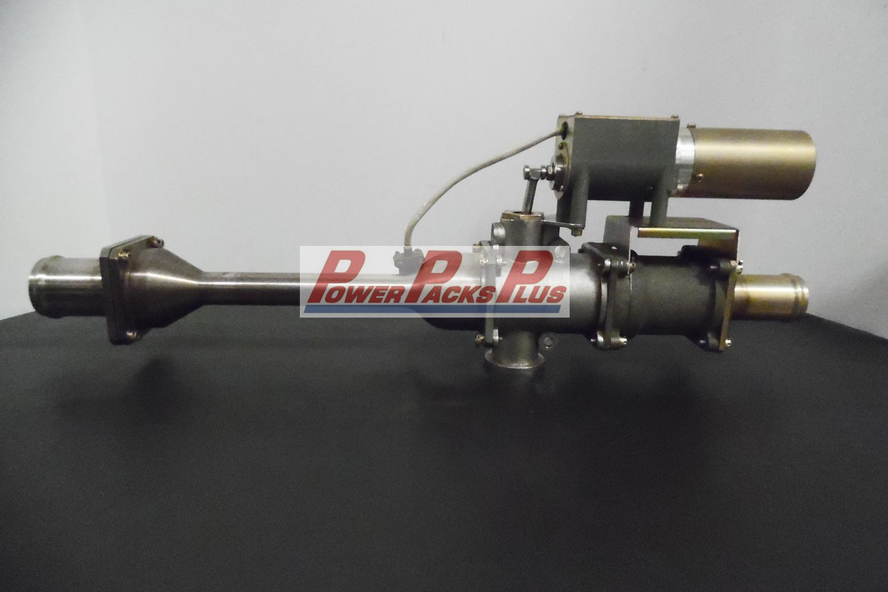

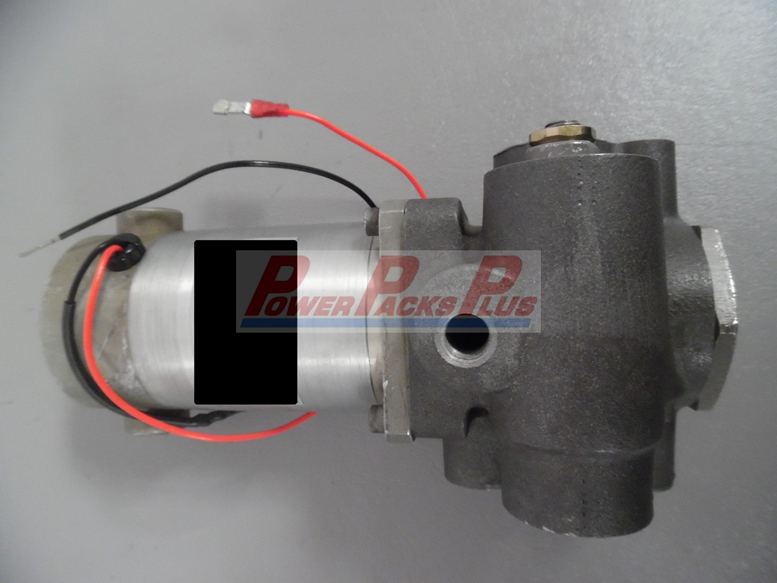

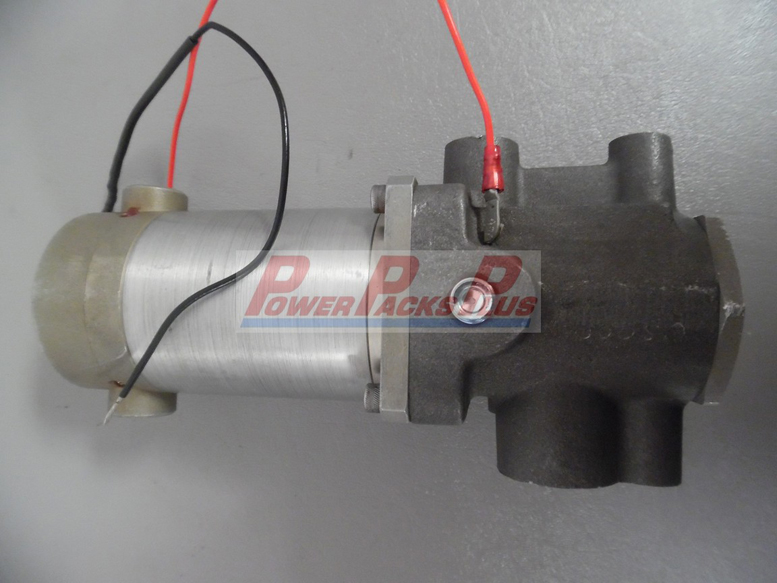

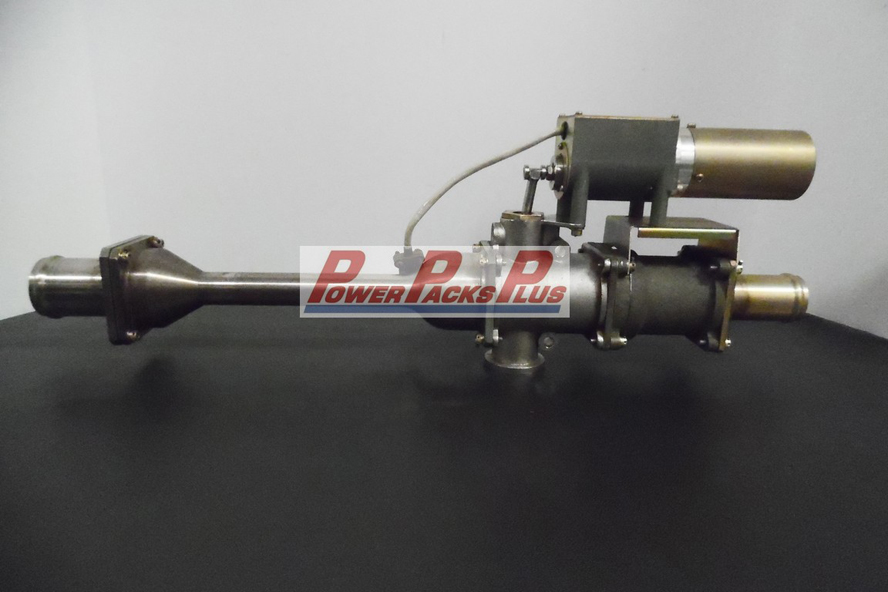

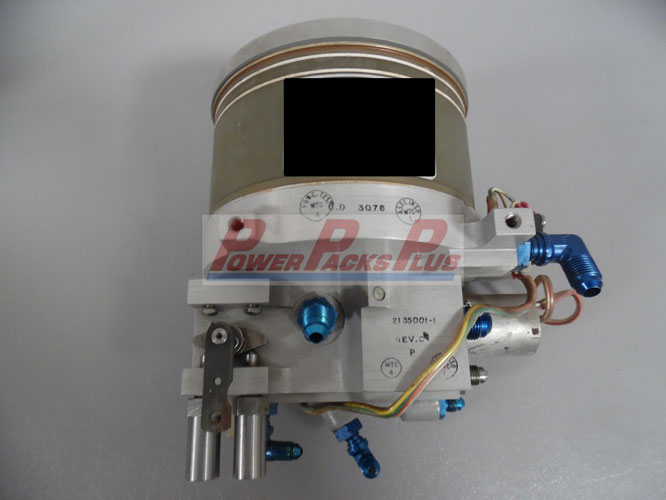

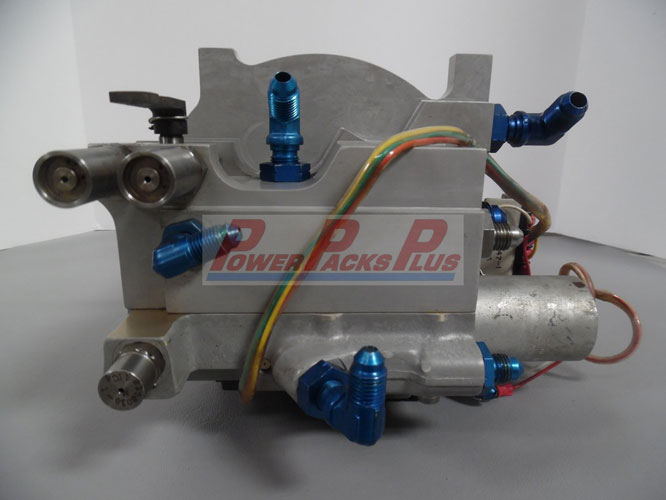

PPEV3-008-EA2A POWER PACK ASSEMBLY – HYDRAULIC

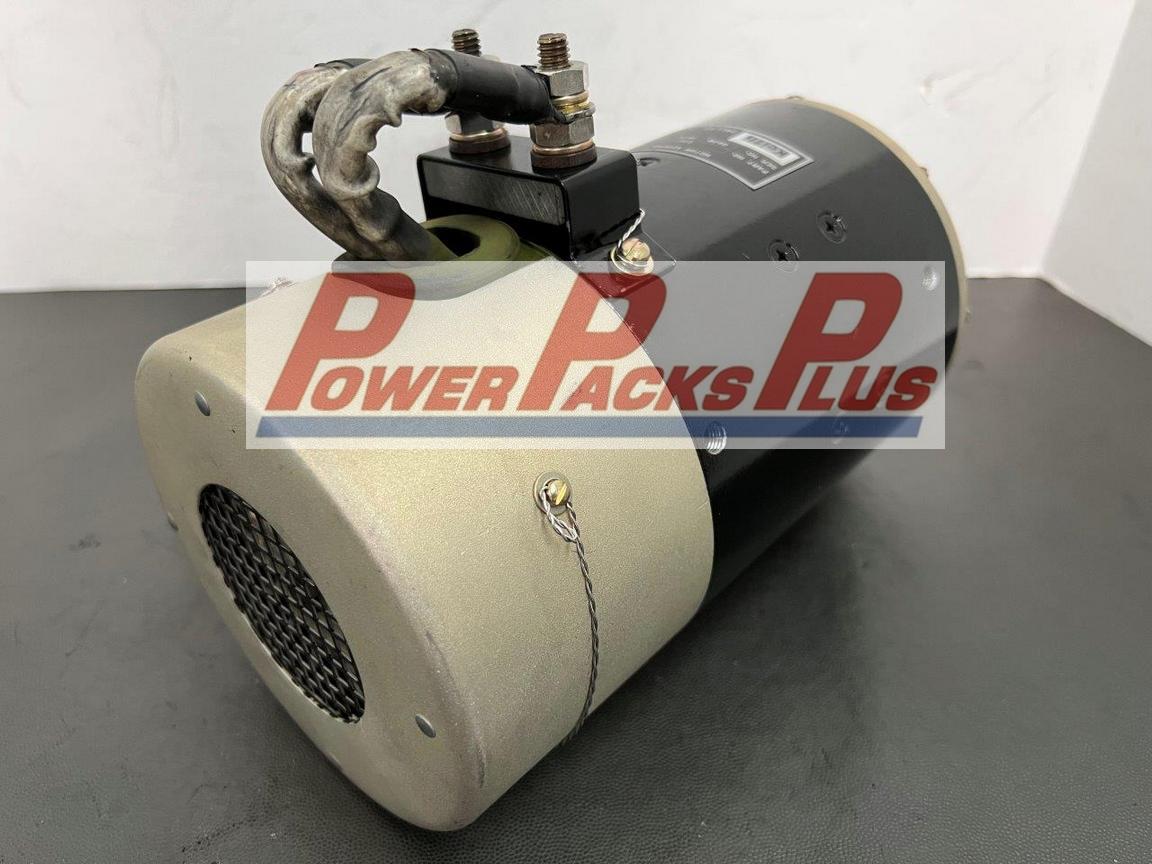

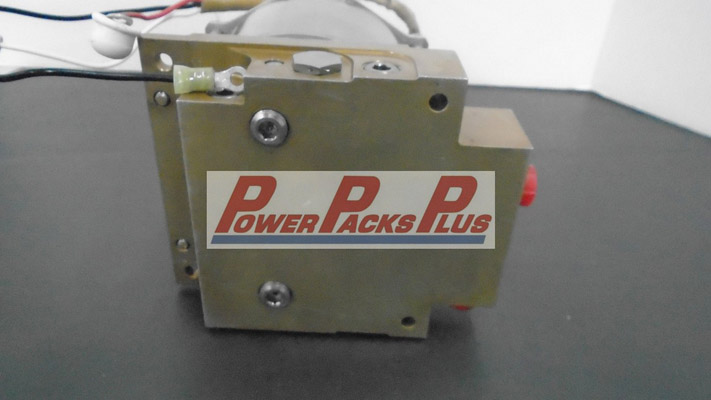

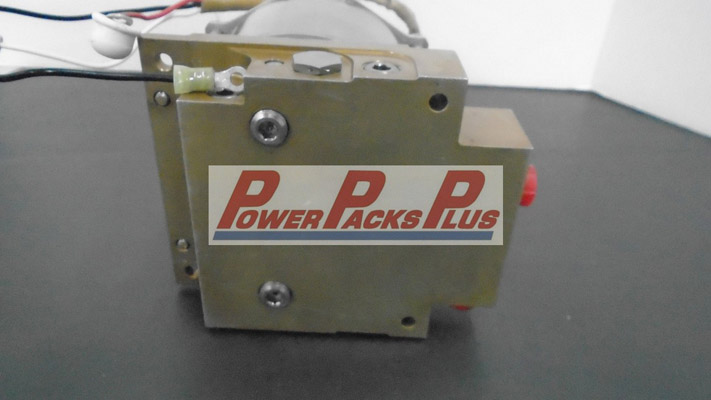

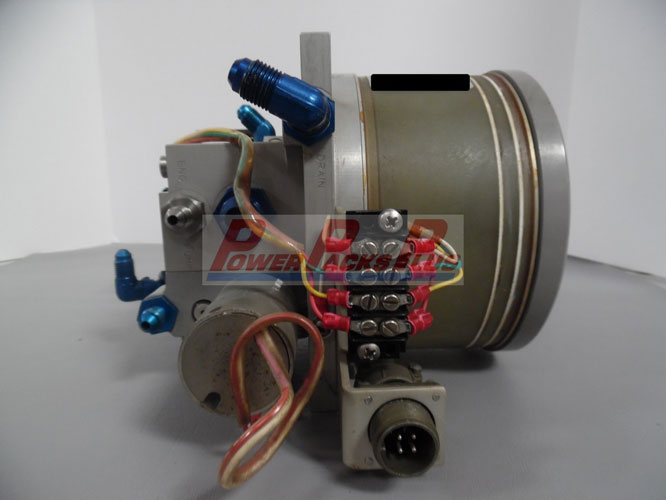

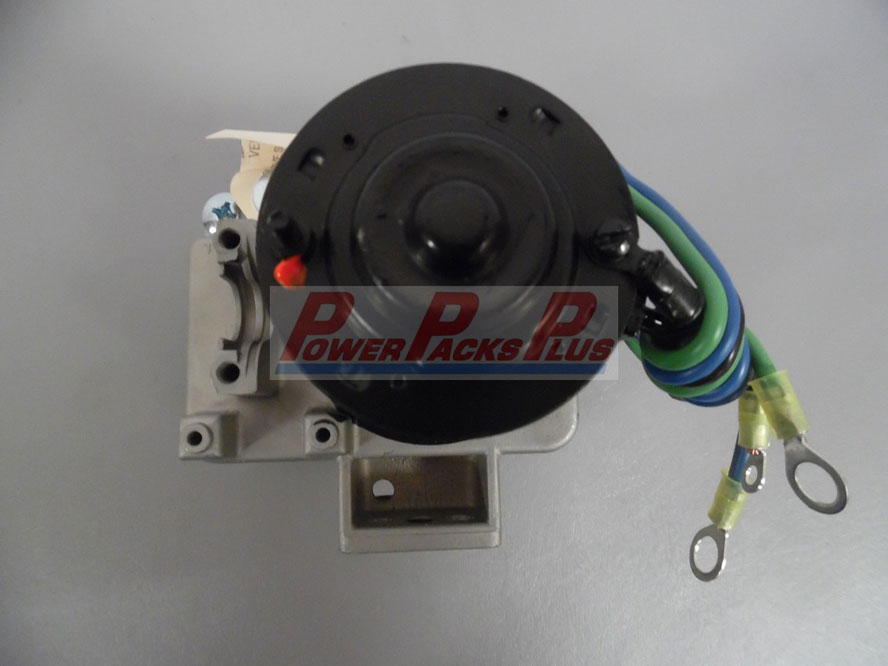

MB86B-6 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

MB86B-4 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

ES61110-3 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

520814 POWER PACK ASSEMBLY – HYDRAULIC

50200-4 POWER PACK ASSEMBLY – HYDRAULIC

18800-5 POWER PACK ASSEMBLY – HYDRAULIC

99-388002-15 POWER PACK ASSEMBLY – HYDRAULIC

27-81009-15 POWER PACK ASSEMBLY – HYDRAULIC

27 81009 015 POWER PACK ASSEMBLY HYDRAULIC

Aircraft Parts Company

Aircraft Parts

Introduction

There are many different types of aircraft parts, and each has a specific function. In this article, we’ll take a look at some of the most important ones. From the cockpit to the engine, learn about the different parts that keep an aircraft up in the sky!

What are aircraft parts?

Aircraft parts are the various components that make up an aircraft. These parts can be divided into three main categories: airframe, powerplant, and avionics. The airframe of an aircraft includes the fuselage, wings, and landing gear. The powerplant of an aircraft provides the propulsion, typically through one or more engines. The avionics of an aircraft include the electronic systems that manage the aircraft’s flight and navigation.

The different types of aircraft parts

There are many different types of aircraft parts, and each plays a vital role in the function and safety of the aircraft. Here is a look at some of the most common aircraft parts:

• Fuselage: The fuselage is the main body of the aircraft, and it houses the cockpit, passenger cabin, and other key components.

• Wings: The wings provide lift and stability to the aircraft, and they are typically attached to the fuselage.

• Engines: The engines provide power to the aircraft, and they are usually mounted on the wings.

• Landing Gear: The landing gear helps to support the weight of the aircraft during takeoff and landing, and it also helps to slow down the aircraft when it lands.

• Tail: The tail helps to stabilize the aircraft in flight, and it is usually attached to the back of the fuselage.

The importance of aircraft parts

As an aircraft mechanic, you know that every part on an airplane is important. But do you know why? Aircraft parts are essential to the safe operation of the aircraft and the comfort of the passengers. Here are a few reasons why:

Aircraft parts keep the aircraft safe. Every part on an airplane has a specific function and purpose. For example, the landing gear helps support the weight of the airplane during takeoff and landing. The engine provides power to fly the plane. And the wings provide lift.

Aircraft parts make flying comfortable. You might not think about it when you’re up in the air, but aircraft parts play a big role in making your flight comfortable. The pressurization system keeps the cabin air at a comfortable pressure. The heating and air conditioning system keeps the cabin temperature just right. And the soundproofing material helps reduce engine noise so you can enjoy a peaceful flight.

Aircraft parts help reduce environmental impact. Today’s airplanes are designed to be more fuel-efficient and have less of an impact on the environment. New materials and technology help reduce emissions and noise levels. And lightweight aircraft parts help save fuel and reduce carbon dioxide emissions.

So next time you’re aboard an airplane

How aircraft parts are made

Aircraft parts are made using a variety of methods, depending on the materials involved and the desired final product. For example, metals may be cast, forged, machined, or formed into shapes using specialised equipment. Non-metallic materials may be molded, shaped, or extruded into parts.

The manufacturing process for aircraft parts is highly regulated to ensure that all parts meet the strictest safety standards. Parts must undergo extensive testing before they can be approved for use on an aircraft. Even after a part has been approved, it must be regularly inspected to ensure that it remains in good condition.

Making aircraft parts is a complex and challenging process, but it is essential to the safe operation of aircraft.

The future of aircraft parts

As the aviation industry continues to evolve, so too must the aircraft parts that keep our planes in the air. With new technologies and materials being developed all the time, it’s important to stay ahead of the curve when it comes to aircraft parts. In this blog, we’ll take a look at some of the latest innovations in aircraft parts and what they could mean for the future of aviation.

One area that is seeing significant advancements is in the area of 3D printing. This technology is being used to create aircraft parts that are lighter and stronger than ever before. By using 3D printing to create parts, there is less waste and less need for expensive tooling. This means that aircraft can be built faster and more efficiently.

Another area of aircraft parts that is seeing innovation is in the area of sensors. Sensors are being used to monitor everything from engine performance to cabin temperature. This data can then be used to improve the performance of the aircraft and make sure that passengers are comfortable.

These are just a few examples of the kinds of innovations that are happening in the world of aircraft parts. As the aviation industry continues to grow, so too will the need for new and innovative aircraft parts.

Conclusion

There are a variety of aircraft parts that work together to keep an airplane in the air. Each part has a specific purpose and must be maintained in order to ensure safe flight. Although there are many different parts, they can all be categorized into four main groups: the powerplant, the fuselage, the wings, and the control surfaces. Understanding how each of these parts works is essential to keeping an airplane flying safely.

- 102559-004 POWER PACK ASSEMBLY – HYDRAULIC

- 102559-003 POWER PACK ASSEMBLY – HYDRAULIC

- 102559-002 POWER PACK ASSEMBLY – HYDRAULIC

- 461-770 POWER PACK ASSEMBLY – HYDRAULIC

- 461-768 POWER PACK ASSEMBLY – HYDRAULIC

- 461-751 POWER PACK ASSEMBLY – HYDRAULIC

- 1FA13059-3 POWER PACK ASSEMBLY – HYDRAULIC

- 1FA13059-2 POWER PACK ASSEMBLY – HYDRAULIC

- 1FA13059-1 POWER PACK ASSEMBLY – HYDRAULIC

- OAS2930-5 POWER PACK ASSEMBLY – HYDRAULIC

102559-004 POWER PACK ASSEMBLY – HYDRAULIC

102559-003 POWER PACK ASSEMBLY – HYDRAULIC

102559-002 POWER PACK ASSEMBLY – HYDRAULIC

461-770 POWER PACK ASSEMBLY – HYDRAULIC

461-768 POWER PACK ASSEMBLY – HYDRAULIC

461-751 POWER PACK ASSEMBLY – HYDRAULIC

1FA13059-3 POWER PACK ASSEMBLY – HYDRAULIC

1FA13059-2 POWER PACK ASSEMBLY – HYDRAULIC

1FA13059-1 POWER PACK ASSEMBLY – HYDRAULIC

OAS2930-5 POWER PACK ASSEMBLY – HYDRAULIC

OAS2930-3 POWER PACK ASSEMBLY – HYDRAULIC

OAS2930-1 POWER PACK ASSEMBLY – HYDRAULIC

1300440-1 SENSOR ASSEMBLY – CABIN TEMPERATURE

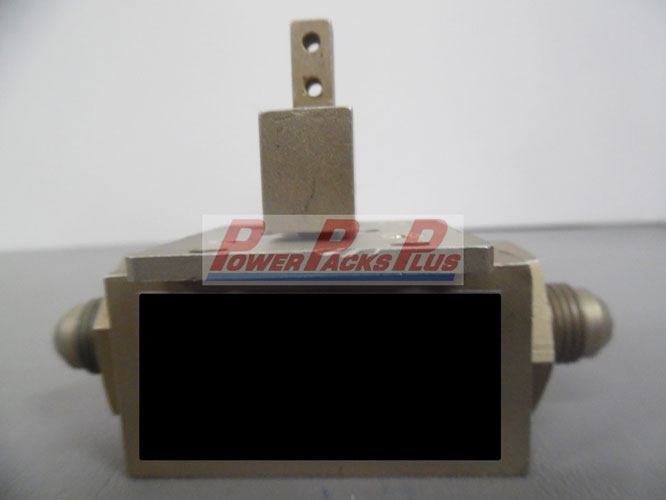

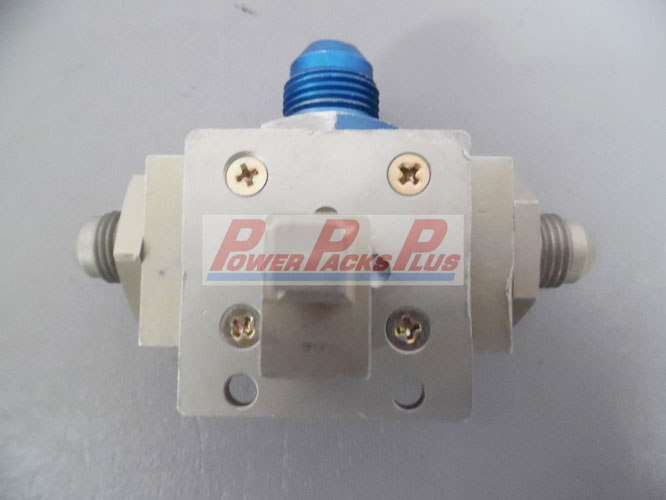

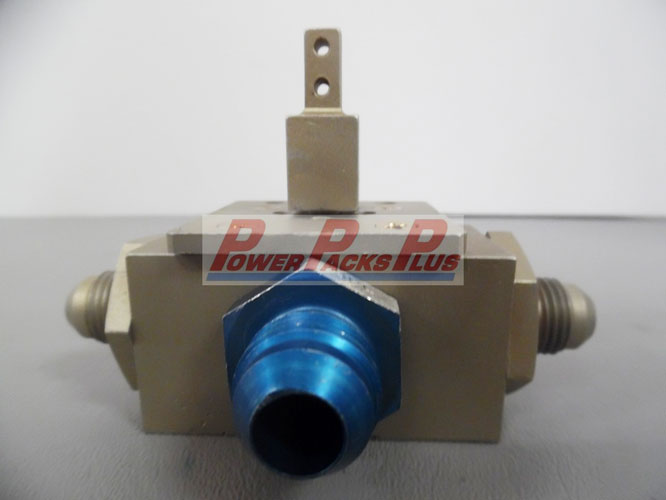

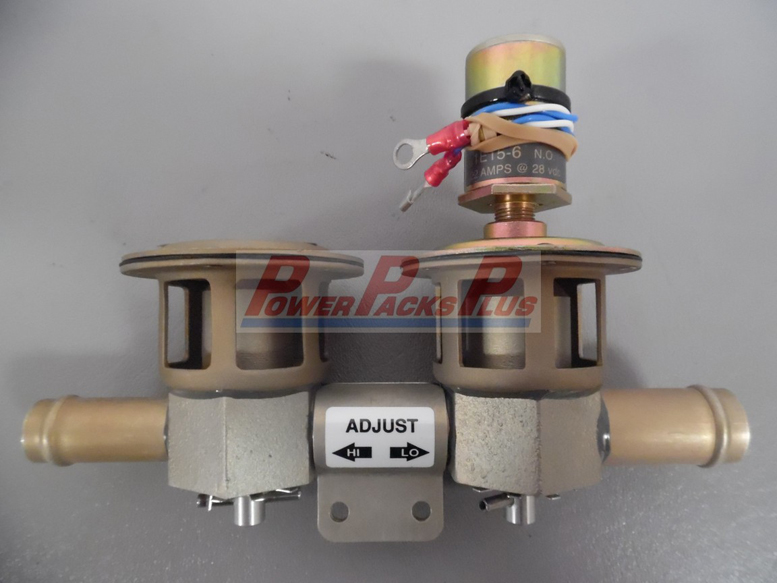

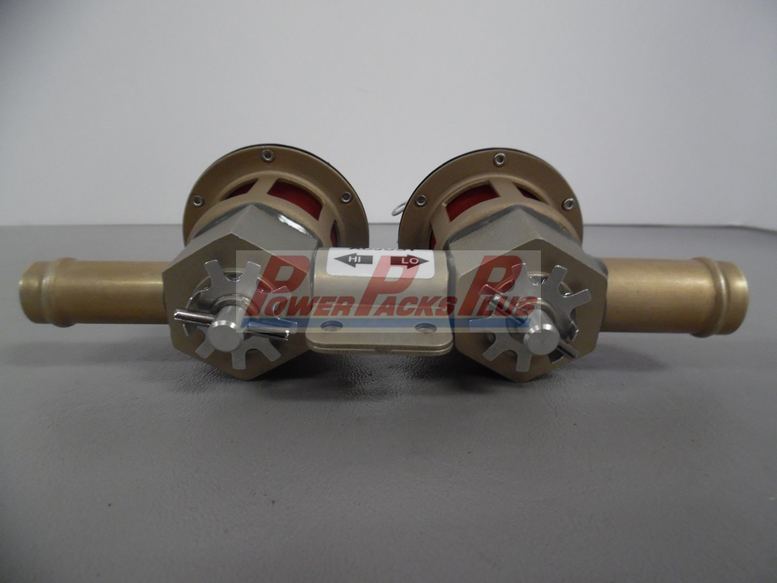

1300330 VALVE ASSEMBLY – TEMPERATURE CONTROL

1240100 CONTROLLER – AUTO LOAD SHED MODULE

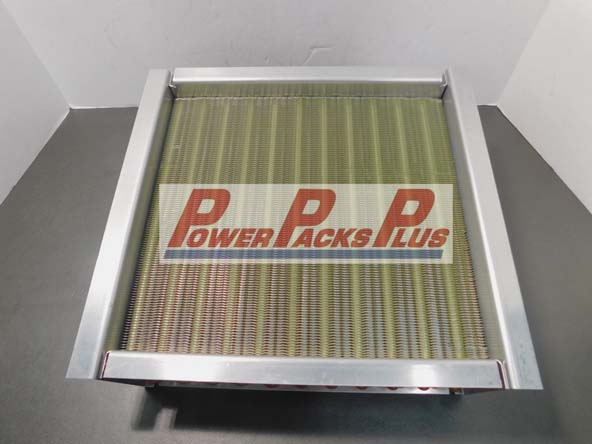

1134177-1 COIL ONLY – AC CONDENSER

1134104-9 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

83956-003 CONDENSER ASSEMBLY – AC

552-205 COIL ONLY – AC CONDENSER

Are You Prepared for The Coming Tsunami of Demand for Air Services?

As the global pandemic hit, the airline industry was one of the first casualties. As airlines around the world grounded their fleets because countries imposed strict no-fly policies. Even demand for private and charter flights nosedived. Obviously, with airplanes grounded, the need for service and parts trickled. Depending on which analysts you believe, the repaired, overhauled and serviced parts business dropped more than 85%.

All that’s about to change, and unless you’re preparing for it, you may miss the opportunity of a quick recovery.

Prepare for Takeoff

We now see green shoots beginning to sprout, and demand for local, regional and international flights is gradually resuming. What’s the state of your grounded flights? What plans do you have to move forward with all those repair and maintenance requests that you pushed to the back burner? It’s never too late to start planning – and PowerPacksplus is your perfect partner to help you get your fleet back into the air.

Risk management experts OliverWyman expect a post-COVID recovery spending boom to provide significant boosts to the aviation industry. In particular, the experts expect one segment of the industry, the used serviceable material (USM) market, to grow at an unprecedented 68% PA through 2022. The forecast is for the market to reach a spending level of nearly $8 billion. The used parts alternative market – also known as special repairs (DER) – is expected to see annual growth levels in the 55%-plus range through 2022.

Insuring Your Own Future

When that market opens up, there’ll be a major upsurge in demand for overhauled, repaired, and otherwise serviceable aircraft components. It’s very likely that, as a result of the skyrocketing need for such parts, prices will move higher too, as every available part source will be tapped by deep-pocketed local and regional airlines and aircraft repair shops. Where will that leave you? Your own parts sourcing team may have a challenge finding the right parts to keep your or your client’s planes flying safely.

That’s where our team can help!

If you want to ensure your fleet remains airborne as future demand for air services is about to pick up, then we can help. At PowerPacksPlus, we have an expanding inventory of a backordered, discontinued, re-furbished power packs and other serviceable parts. It matters not whether the aircraft is a Socata, Beechcraft single/multi, Cessna Bellanca, Rockwell or Piper…if no one else can find what you’re looking for, chances are that we either have it in stock, or can get it for you! How can we say that with such certainty? Because we worked hard to build a reliable global network!

We’re Here to Help

We’ve been in the business for a long…long time, cultivating and carefully building our vast national and international network of OEMs and slightly-used parts suppliers. Our team of experts have their fingers on the pulse of the global supply chain, keeping track of what demand is out there, and where there’s supply.

When your in-house team is at their wits end trying to source that one-of-a-kind made-to order component, chances are that we know exactly where there’s someone that has what your planes need to take off. And if your team has parts that have been on backorder for months -with no hope for delivery on the horizon, chances are that we can expedite delivery, either through our extensive in-house parts inventory, or through our own elaborate supplier networks.

If you need powerpacks or other hard-to-source parts and components, then just contact us – we’re here to help!

Are You Prepared for The Coming Tsunami of Demand for Air Services?

All that’s about to change, and unless you’re preparing for it, you may miss the opportunity of a quick recovery.

Prepare for Takeoff

We now see green shoots beginning to sprout, and demand for local, regional and international flights is gradually resuming. What’s the state of your grounded flights? What plans do you have to move forward with all those repair and maintenance requests that you pushed to the back burner? It’s never too late to start planning – and PowerPacksplus is your perfect partner to help you get your fleet back into the air.

Risk management experts OliverWyman expect a post-COVID recovery spending boom to provide significant boosts to the aviation industry. In particular, the experts expect one segment of the industry, the used serviceable material (USM) market, to grow at an unprecedented 68% PA through 2022. The forecast is for the market to reach a spending level of nearly $8 billion. The used parts alternative market – also known as special repairs (DER) – is expected to see annual growth levels in the 55%-plus range through 2022.

Insuring Your Own Future

When that market opens up, there’ll be a major upsurge in demand for overhauled, repaired, and otherwise serviceable aircraft components. It’s very likely that, as a result of the skyrocketing need for such parts, prices will move higher too, as every available part source will be tapped by deep-pocketed local and regional airlines and aircraft repair shops. Where will that leave you? Your own parts sourcing team may have a challenge finding the right parts to keep your or your client’s planes flying safely.

That’s where our team can help!

If you want to ensure your fleet remains airborne as future demand for air services is about to pick up, then we can help. At PowerPacksPlus, we have an expanding inventory of a backordered, discontinued, re-furbished power packs and other serviceable parts. It matters not whether the aircraft is a Socata, Beechcraft single/multi, Cessna Bellanca, Rockwell or Piper…if no one else can find what you’re looking for, chances are that we either have it in stock, or can get it for you! How can we say that with such certainty? Because we worked hard to build a reliable global network!

We’re Here to Help

We’ve been in the business for a long…long time, cultivating and carefully building our vast national and international network of OEMs and slightly-used parts suppliers. Our team of experts have their fingers on the pulse of the global supply chain, keeping track of what demand is out there, and where there’s supply.

When your in-house team is at their wits end trying to source that one-of-a-kind made-to order component, chances are that we know exactly where there’s someone that has what your planes need to take off. And if your team has parts that have been on backorder for months -with no hope for delivery on the horizon, chances are that we can expedite delivery, either through our extensive in-house parts inventory, or through our own elaborate supplier networks.

If you need powerpacks or other hard-to-source parts and components, then just contact us – we’re here to help!

ES73171-4 BLOWER ASSEMBLY – AC CONDENSER

ES61137-1 MOTOR ASSEMBLY – AFT EVAPORATOR, BRUSHLESS DC

2576562-4 SERVO ASSEMBLY – FUEL INJECTION

2549038-4 SERVO ASSEMBLY – FUEL INJECTION

0106-T3 SERVO ASSEMBLY – AUTOPILOT

0106-11-T8 SERVO ASSEMBLY – AUTO PILOT

1300360-13 CONTROLLER ASSEMBLY – MASS FLOW

1300350-13 CONTROLLER ASSEMBLY – CABIN TEMPERATURE

1133210-16 MOTOR ASSEMBLY – EVAPORATOR BLOWER

1133210-15 MOTOR ASSEMBLY – EVAPORATOR BLOWER

1133210-11 MOTOR ASSEMBLY – EVAPORATOR BLOWER

1133010-14 BLOWER ASSEMBLY – CONDENSER, AC

ES73176-1 BLOWER ASSEMBLY – EVAPORATOR, REAR

ES73127-2 BLOWER ASSEMBLY – AC CONDENSER

ES61134-3 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

ES61110-4 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

BC61A-901-2 BLOWER ASSEMBLY – CABIN VENTILATION

AI-BA128A-1 BLOWER ASSEMBLY – CONDENSER

9914416-1 POWER DRIVE UNIT – FLAP

1250104 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

1250104 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

1134104-6 MOTOR ASSEMBLY – COMPRESSOR DRIVE

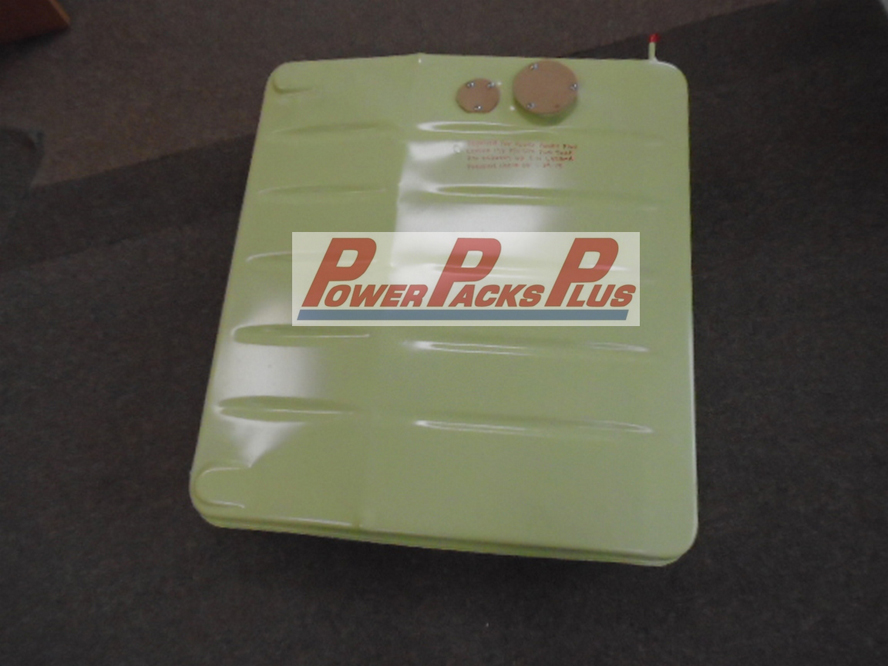

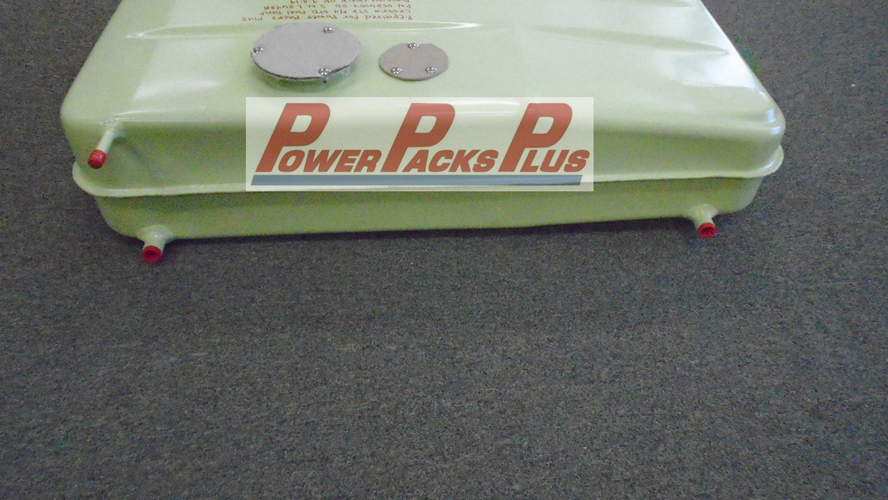

0526007-205 TANK ASSEMBLY – STANDARD FUEL LH

0526007-204 TANK ASSEMBLY – STANDARD FUEL LH

0526007-201 TANK ASSEMBLY – STANDARD FUEL LH

0526007-62 TANK ASSEMBLY – FUEL RH STANDARD

0526007-50 TANK ASSEMBLY – FUEL RH STANDARD

0526007-44 TANK ASSEMBLY – FUEL RH STANDARD

9914615-3 POWER DRIVE UNIT – FLAPS

1300490-21 VALVE ASSEMBLY – FLOW CONTROL

1300490-11 VALVE ASSEMBLY – FLOW CONTROL

0108-P4 SERVO – AUTOPILOT

0108-17-P4 SERVO – AUTOPILOT

0107-P4 SERVO – AUTOPILOT

0106-R9 SERVO – AUTOPILOT

0105-T10 SERVO – AUTOPILOT

0105-R9 SERVO – AUTOPILOT

9912733-3 STARTER GENERATOR

9912733-3 STARTER GENERATOR

1250151 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

1250151 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

1134200-65 EVAPORATOR BLOWER ASSEMBLY-RH

1134200-64 EVAPORATOR BLOWER ASSEMBLY – LH

1134104-5 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

1133480-1 BLOWER ASSEMBLY – CONDENSER

1133210-22 MOTOR ASSEMBLY – EVAPORATOR BLOWER, RH

1133210-21 MOTOR ASSEMBLY – EVAPORATOR BLOWER, LH

1133210-17 MOTOR ASSEMBLY – EVAPORATOR MODULE

1131326 COMPRESSOR ASSEMBLY, AC

The art and science of finding high-quality aircraft parts online

Providing your maintenance crew with high-quality parts is equal part art as it is a science. Aircraft owners, be they industrial, commercial or personal craft, must not overlook this fact when building an aircraft parts and components sourcing strategy.

In search of quality online

The search for components typically starts online. Busy sourcing specialists may think a quick Google search will save them tones of time working the phones or sending emails to hundreds of air craft parts and component suppliers. And that’s where the art saves the day. Knowing what to search for will help get you what you need – correct?

Well – not exactly! When you’re racing against time, looking for a long-discoed part, a unique made-to-order component or a typically hard-to-find module, it’s hard to distill 362-million search results to source precisely what you need!

Well, a good online search artist could easily cut down that volume by doing a creative online search couldn’t they?

Not entirely true! Even if you refine your search by including more specific keywords – like “high quality” – you’ll likely end up with an unmanageable list to comb through. How do you choose a reliable sourcing partner from a list of 160-million names? It’s humanly impossible.

Finding high-quality online

When looking for high-quality aircraft components and parts online, it’s often more effective to use a scientific approach to find the right partner, and then apply the art of working jointly with your supplier to get what you need – when you need it. And to do that, you won’t need 362-million, 160-million or even a hundred choices. The only place to turn to, when looking for high-quality components and parts is PowerPackPlus (PPP).

Sourcing discontinued parts online can be a real challenge. Finding custom-manufactured made-to-order parts through Google searches is nearly impossible. Securing back-ordered components on your own can be a nightmare. However, The extensive and painstakingly-curated PowerPacksPlus inventory database makes the art of finding the right part online that much simpler.

Google-searching online for A/C compressors, Electric Motors, Horizon Indicators, Hydraulic Pumps, Landing Gears, Fuel Injection Servos or Stall Warning components requires scientific knowledge of part specs and intended usage. And the science gets more complex when you add multiple aircraft to the mix – Beechcraft, Cessna, Piper or Grumman. But with a seasoned aircraft components sourcing partner like PPP working with you, highly knowledgeable staff turn that science into art form to get you the high-quality components you want for the right application.

Make the best of high-quality

So, instead of scouring the internet and trying to build a sourcing network of your own, why not leverage the years of experience and hard work already available. Contact PowerPackPlus with your aircraft component needs, and watch the team bring art and science together to source high-quality components that exceed your expectations.

RG9080-J4A PUMP ASSEMBLY – ENGINE DRIVEN FUEL

ES73175-2 BLOWER ASSEMBLY – FWD EVAPORATOR

C52807-2 TRANSDUCER ASSEMBLY – LIFT

C52806-2 COMPUTER ASSEMBLY – LIFT

1134160 COMPRESSOR ASSEMBLY – AC

636294 HYDRAULIC POWER PACK

636029 HYDRAULIC POWER PACK

74118-LAB MOTOR – HYDRAULIC

74118-LAA MOTOR – HYDRAULIC

6305 MOTOR – CONDENSER BLOWER

Aircraft part sitemap for PPP

www.powerpacksplus.com/sitemap.xml

Part number: 9910136-8 Alternate part number: 1521200-9

MFR: Tejin Seki

APPLICATION: Cessna

DESCRIPTION: Main Gear Actuator

Cessna aircraft parts by Power Packs Plus

38998-7

38998-07 HYDRAULIC POWER PACK

38998-007 – HYDRAULIC POWER PACK

38998-005 HYDRAULIC POWER PACK

8537 TRANSMISSION ASSEMBLY – FLAP

8407 TRANSMISSION ASSEMBLY – FLAP

114-388000-13 HYDRAULIC POWER PACK ASSEMBLY 1

114-388000-9 HYDRAULIC POWER PACK ASSEMBLY

Sourcing Aviation Parts & Components: When time means everything

But one area of the aviation business, where time means everything, doesn’t often receive the attention it deserves: Aviation parts and components sourcing!

Only part of the story

If you are in the aviation business, you likely know of the challenges your maintenance crews face sourcing back-ordered, discontinued or made-to-order parts used by your own or customer aircraft or fleet. Typically, though, a sourcing specialist may say: It may be difficult to locate, but give me more time and money and I’ll find us that part.

The underlying connotation is that, given more time to source a hard-to-find component, money will resolve any challenge of difficult to source parts. But, that’s just part of the story. Owners of aviation businesses know that the true cost of locating a hard to find part seldom reflects the price you pay for it. And here’s why:

- While you may sometimes pay premium rates for a backordered (or discontinued) part, you’ll have spent more than that in terms of the time your staff spent on locating the part

- No one today – especially staff working in challenging environments – has enough time in the day to do what they must. Like in most fast-paced businesses, the aviation industry also places a premium on scarce time. But we hardly ever factor that into the overall cost of a hard-to-locate part

- Often, more than just money, time also means opportunity! If your staff weren’t engaged in scouring the internet (and their own supply chain sources) to find that elusive component, assuming other channels delivered the missing part to them, could they have spent that time more productively addressing issues caused by the missing part?

- And then, time also equates to missed opportunity! In many instances, aviation business managers and decision makers spend countless hours a month addressing component sourcing challenges. A text message here, an email there, a couple of quick phone calls, a face-to-face Skype meeting…it all adds up. Think of the new business you and your staff could have pursued in that time, were it not spent tracking down hard-to-locate parts? The thing about missed opportunities is: They’re never missed – someone else (your competitor?) grabs them!

So, while we do acknowledge that time is money, there’s more to time than just dollars and cents. Sometimes, when we’re hot on the tracks of a made-to-order component or a long-discoed part, we lose sight of the fact that time is everything – from cost savings to excess cost, and from delayed projects to missed opportunities.

Make the most of your time…and your money

Because time does mean everything in today’s digital age, more and more aviation businesses are looking to make the most of it. And how are they doing that? By turning to specialist aviation parts and component sourcing companies, like PowerPackPlus (PPP), for help. So, what value might such companies offer?

- You have a business to manage and operate, and your staff have other pressing tasks to tend to. Delegating the task of locating hard-to-come-by parts to specialist parts locators leaves you and your staff with more time to run your business

- Cultivating an elaborate network of component sources takes time – which ultimately translates to money! So, why invest money building such a network, when you can partner with aviation component and parts specialists that already have such networks? They do this as their primary – and only – job, so you may benefit from the time and money they’ve invested. Why not leverage their investment to your advantage?

- When it comes to scarce components and hard to source parts, typically, aviation business operators, mechanics and maintenance shops play it safe. Because of the extraordinary amounts of time and resources it takes to locate such components, they’ll maintain an in-house stock – which ties up a lot of working capital. So, if someone said you don’t need to tie up all that money in parts – because we either have them in stock or will source them for you on an as-needed basis – what would you say?

Well, most business owners would gleefully say: Sure, why not! And you could promptly reallocate capital, previously tied to parts and component inventory, to other aspects of your business.

Parts sourcing companies make a living by stocking and sourcing overhauled, repaired, and otherwise serviceable inventory of back-ordered, discontinued and made-to-order items and other aviation components and parts. If you, as an aviation business operator – whether you charter, own, repair or maintain aircraft – want to make the most of your time and money, one way to do that is to work with a trusted industry parts and component locators.

Your source of hard-to-source parts

Here at PowerPacksPlus, we strive to be your single window source of difficult to find aviation parts and components. Whether it’s a specialty, one-of-a-kind made-to order component, something that’s been on backorder for months, or one that’s discontinued by the OEM – we’ll get it for you! It doesn’t matter what make, model or vintage of aircraft you own, operate or service – Beechcraft single/multi, Bellanca, Cessna, Piper, Rockwell or Socata – if you’re in search for Power Packs, we’re here to support you.

Need other components for these and other aircraft? A/C compressors, Gauges, Valves, Motors, Fuel Pumps? No matter what the component is – If we don’t already have it in inventory, we’ll source it for you. If there’s a source anywhere in the world, that has the part you’re looking for, our component sourcing specialists will unearth it and secure the part for you.

So, how do we do it? The short answer – experience and expertise!

With more than three decades in the parts locating business, our sourcing specialists have deep links within the global aviation components industry. From OEMs and licensed manufacturers, to refurbishing operations and repair shops – our extensive network covers them all. That’s how we’ve evolved into one of the most resourceful aviation parts locating company in the business.

If time indeed means everything to you, why not contact us and see how we might save time, money and lost opportunity for your business!

MD160-2-INDICATOR MP FF

MD165-1 INDICATOR – TACHOMETER

MD163-2 INDICATOR – DUAL FUEL

MD162-3 INDICATOR – OP, OT

MD161-1 INDICATOR – EGT, CHT

MD160-2 INDICATOR – MP, FF

13557-001-INDICATOR-ASSY-DUAL-FUEL-QTY

Access high-quality refurbished aircraft parts – and keep your fleet in the air!

Aviation is a highly competitive industry. Whether it’s for sport, leisure, personal or business use, your aircraft (individually or collectively as a fleet) represent a huge source of investment, pose large risks and offer big opportunities. And along with those three imperatives comes the pressure to manage costs. That’s why more aircraft owners are turning to the use of refurbished aircraft parts to assuage these competitive pressures.

It takes more than hot air…

…to keep your fleet flying safely!

Sadly, that’s all that some parts dealers can offer you. With promises of on-time delivery and unlimited inventory, you may think you’re getting a good deal, but can you really stake it all on promises alone? With so much at stake, including lives, safety in the air should be your paramount concern.

Following a string of high-profile aviation incidents involving both large and small craft, regulators are also taking note. Aircraft safety has prompted stringent regulatory mandates for craft owners and operators. It has become impossible to keep the watchdogs at bay with hot air alone. Working with a reputable refurbished aircraft parts supply channel partner is the best way to stay “on side” with regulatory bodies.

The bane of AOG

Unscheduled and protracted Aircraft On Ground (AOG) instances can be particularly impactful to craft owners/operators, especially if the craft is not flight worthy because of parts shortages. Depending upon the length of time an ongoing AOG situation drags on for, it could cost craft owners hundreds or even thousands of extra dollars – money that you would not otherwise have spent.

While mint-condition OEM parts may be a desirable solution to prevent prolonged AOG situations, such parts are either too costly, difficult to source or come with extended lead times. Unlike refurbished aircraft parts, new components might also not be readily available for craft of a specific make, model or vintage. This predicament leaves large fleets of aircraft grounded for long periods, sending owners and repair crew scrambling to source the right part for a reasonable price within a realistic timeframe.

Owners of large fleet of aircraft have recourse to many practical maintenance strategies to keep AOG at minimum. Typically, maintenance crew will “borrow” a much-needed part from one craft, just to make sure another craft is up in the air on time to complete a scheduled trip. Sure, that move could potentially reduce AOG time for one craft – but it leaves the other grounded for an extended period.

“Borrowing” or “pirating” parts is a perfectly legitimate maintenance strategy. But, if you own a fleet of similar craft, you may soon find multiple craft grounded because their parts are now in use on a single craft that’s up in the air!

As an owner of a single sport, leisure or commercial craft, your best bet to reduce AOG time is to turn to refurbished aircraft parts to ensure you and your family and friends and your customers benefit from your craft for the longest possible time. Single-craft owners/operators don’t have the luxury of “pirating” or “borrowing”. So, if there’s a parts shortage that’s preventing your craft from becoming airworthy, then an extended AOG situation is all but unavoidable – or is it?

Regardless of whether you own a single craft or a fleet of them – there is an alternative. Tapping into a reliable source of authentic refurbished aircraft parts can help you keep all your craft in the air all the time!

Unbearable BER situations

At times, aircraft owners may face tough choices when striving to keep their craft flying. This predicament stems from having to decide whether to scrap and replace with either new components or refurbished aircraft parts, or to proceed with repairing, even if it’s a Beyond Economic Repair (BER) situation.

According to IATA guidelines:- (2nd Edition 2015, page 13)

“BER is defined as the ratio of repair cost to the value of the part at which a part is scrapped or repaired. If this ratio exceeds a predefined value, the part is considered as BER and will be scrapped”

All parts and components have a useful life that maintenance specialists recommend you typically should not (even if you can!) exceed. Some parts, once removed and sent to a maintenance shop, turn out to be too costly to repair. Often, in a Beyond Economic Repair (BER) situation, refurbished aircraft parts may be the most viable and cost-effective maintenance strategy.

Professionally repaired, refurbished and overhauled aircraft components and parts provide a dependable solution for aircraft owners/operators for whom BER scenarios are untenable. In most cases, even if the owner does decide to move ahead and repair a BER component, the quality of service and durability of the part could potentially be suspect.

Comparably, refurbished aircraft parts on the other hand offer better value for money. Here’s why:

- Typically, you may be tempted to accept the BER cost, and move forward with repairing a defective component when you compare that estimate to the catalogue price of an equivalent new part. That comparison is misleading! A truer “apples for apples” comparison would be to match BER estimates against similar-vintage pre-used or refurbished aircraft parts

- Even after your part returns following a BER maintenance “fix”, it isn’t restored “just like new”. The nature of component repair is such that reviving BER parts to “like new” form just isn’t possible! When you factor that reality into the equation, repaired and restored parts and components then become a better economic proposition to BER

- Finally, once a BER “fixed” part does make it back into service, it will likely need extra care, inspection, attention and monitoring throughout it’s time-on-wing (useful life) – more so than equivalent refurbished aircraft parts And all that additional Tender Love & Care (TLC) means more cost to the aircraft owner/operator!

The bottom line: Once you factor all these elements into the equation, using repaired BER components instead of refurbished aircraft parts may not be good for your bottom line after all! And that’s why more owners and operators look to form alliances and establish relationships with refurbished part dealers.

The math of refurbished aircraft parts

The math of extended fleet grounding, frequent unscheduled maintenance and regularly-disrupted schedules is simple: It costs money – lots of it! Refurbished aircraft parts and other repaired and fully-tested, reliable and airworthy components can save you a lot of money!

Ask any owner/operator and they’ll likely confirm that they would prefer as much as possible to avoid unnecessarily extended AOG scenarios. When you do an addition of all the associated costs, the math just won’t add up!

And, for BER situations, the math is even simpler. While the IATA guidelines suggest:

“A typical value for this {BER} threshold is set at 60-70% of the cost for replacement (i.e. catalog list price)…”

The organization also holds that:

“An industry practice is to scrap a part as long as it is BER”

What this means is that, when you do the math to work out the total cost of longer than necessary delays in getting your aircraft back in the air, or using parts that are uneconomical to repair and re-use, using refurbished aircraft parts will always be a more economical option. You just can’t work the numbers any other way!

But there’s more to it than simple math.

As with most industrial or commercial transactions, there’s usually more than just money at stake when it comes to not having an aircraft available on time, every time. At some point, something more valuable than money – your reputation as a dependable partner – will come into play. Whether it’s a sport craft, a personal flight aircraft or a commercial carrier, unscheduled disruptions in plans will also impact the individuals, groups and organizations depending on your craft (or fleet).

Having access to a reliable source of overhauled, repaired and refurbished aircraft parts gives you the peace of mind knowing your fleet will be in the air on-time – every time! While your partners – whether they are individuals, groups or commercial entities – will always give you top-line reviews, your bottom line will remain intact – and even continue to grow.

The PowerPacksPlus difference

So, what does an extended AOG situation mean to you? And is it worth while taking a risk to use BER “fixed” components instead of refurbished ones? These are key questions that only you can address when deciding on which maintenance strategy to adopt.

Whether you own a Beechcraft Single or Multi Engine craft, a Bellanca Viking, Rockwell Commander or a Piper Single or Twin Engine aircraft – it really doesn’t matter. We, here at PowerPacksPlus, have you covered with the widest selection of refurbished aircraft parts and the most experienced sales and advisory teams in the industry.

From Power Packs for a wide range of craft, to Electric Motors, A/C Compressors, Landing Gear, Fuel Selector Valves, we either stock them or have almost instantaneous access to the broadest array of refurbished aircraft parts that you can find anywhere. And, if you can’t find what you’re looking for anywhere else, we’ll use our vast network of contacts to source you exactly what you want – that’s our commitment to you.

Beyond “selling”

As an aircraft owner/operator, whether it’s just a single craft or an entire fleet of them, you want to establish relationships with a team of professionals that think “beyond selling”. And that’s exactly what our team of highly experienced aviation industry experts believe too. When you reach out to us to source your refurbished aircraft parts, you won’t receive any “sales pitches” like you would at a typical “parts reseller”.

The men and women at PowerPacksPlus have deep knowledge and experience of aircraft parts and components. And when you combine that with decades of collective knowledge of the aircraft industry, you have an expectation of deeply personalized service – and that’s precisely what our team are trained to offer!

The refurbished aircraft parts business isn’t exactly like an auto-body shop, where mechanics are motivated to up-sell – whether it’s an Oil Filter or a set of spare tires. Most retail auto consumers don’t have the level of sophisticated knowledge about the parts and components that go into a vehicle. As a result, they are susceptible to dubious selling practices. But we service a clientele who are typically impervious to strong-arm selling!

As an aircraft owner or operator, we know that our customers are very discerning. And that’s why we never really favored the “selling” thing anyway! Our clients value highly objective, honest advice – and that’s exactly what you’ll get when you engage with one of our refurbished aircraft parts team members.

Experience that matters

Your aircraft represents a significant investment to you and, as a result, you’d like to source your parts only from a provider who appreciates that fact. Since our inception back in July 2005, our team has offered solution-focused resolutions to clients looking for refurbished aircraft parts. And that commitment is apparent in our pledge for:

“…providing the best possible solution to keep your business aircraft flying!”

Through the years, we’ve established deep ties with a wide range of aviation industry players – from aircraft manufacturers and OEMs of parts, to maintenance specialists and component repair shops. And it is precisely those ties that our refurbished aircraft parts customers can leverage when they partner with us.

Our partners include the entire gamut of “Who’s Who” of the commercial aircraft industry – from AIRBORNE and BEECH, to CESSNA, CRANE, KING AIR, LEAR, PIPER and beyond. Whether it’s back-ordered parts you need, or discontinued components of a specific vintage that you are looking for, our knowledgeable associates will be able to help you source them.

If there’s a source that can provide you the parts you need, chances are that we already have an established relationship with them. Our network will save you the time and hassle of building a fresh relationship with an unknown source. It also means you’ll automatically benefit from our specially negotiated commercial terms with those sources.

Having our experts on your team also means we’ll be able to source one-of-a-kind made-to-order items for your unique needs. But most of all, having a team of refurbished aircraft parts specialists that know the business, have knowledge of the industry, and speak and understand your “lingo” is critical to keeping those aircraft flying without turbulence!

12615-002 INDICATOR ASSY – DUAL FUEL QTY

12615-002 INDICATOR ASSY – DUAL FUEL QTY

11797-008 MOTOR ASSY – PITCH TRIM

11797-006 MOTOR ASSY – PITCH TRIM

M317M157 MOTOR ASSY – PITCH TRIM

M317M157-MOTOR-ASSY PITCH-TRIM

RG17980DM PUMP ASSY – ENGINE DRIVEN FUEL

RG9570R1-M PUMP ASSY – ENGINE DRIVEN FUEL

0108-15-P4 SERVO ASSY – AUTO PILOT

317A412 MOTOR ASSY – PITCH TRIM

130346-1 CONTROLLER ASSY – CABIN PRESSURIZATION

2524213-11 SERVO ASSY – FUEL INJECTION

FQ4030-12034 INDICATOR ASSY – DUAL FUEL QTY

FQ4041-12037 INDICATOR ASSY – DUAL FUEL QTY

Single Engine Vs. Twin: Pros and Cons

To become a pilot that people can respect, your knowledge of the craft needs to be sky-high. Understanding the difference between twin-engine planes and single-engine planes isn’t enough. You need to know which situation is appropriate for which plane, and how they handle differently.

Learning the difference is the first step towards becoming a better pilot. Keep reading below for everything that you need to know!

Twin-Engine Planes are Powerful and Safer

The biggest difference between twin-engine planes and single-engine planes is their power. Twin-engine planes benefit from the power of having two engines to battle gravity with. That means takeoff is easier and the plane can cut through the sky faster than its single-engine counterpart.

Since twin-engine planes have more than one engine, they’re also safer than single engine ones. If an engine fails, you’re not stuck in the sky, hoping for the best. Instead, you can use the power of the engine you have left to safely land the aircraft.

Twin engine planes combine power and safety to create all-around capable crafts. Being an adept pilot in a twin-engine plane makes you a force to be reckoned with in the sky!

Pilots May Take More Risks with Twin-Engine Planes

Although twin-engine planes are powerful and safe vehicles, they have their shortcomings. The most obvious shortcoming is their cost. You’re doing more than paying for two engines. You’re also paying for the gas to fuel them, and the price can get high quickly.

Since people may be more confident in a twin-engine plane, they may take more risks. It’s counter-intuitive, but the fact that the planes are safer can actually cause pilots to make more mistakes. They can get too confident in their abilities, and that can endanger both the pilot and their passengers.

Single-Engine Planes are Simple and Cheap

While twin-engine planes are powerful and safer, single-engine planes are cheaper. They’re also simpler machines, which makes them easier to maintain and fly. New pilots usually choose single-engine planes because they’re more cost-effective and can last longer than twin-engine planes.

They also consume less fuel than their twin-engine counterparts. Less fuel consumption also means longer flights since the fuel tank will last longer. That means you’ll be able to spend more time where you belong: in the sky!

Pick the Plane that Works for You

There are a lot of advantages and disadvantages of each style of plane. The best way to know which plane to choose is to think about what you value as a pilot. Do you want something that tears through the sky or would you like something simple and inexpensive?

The choice is yours. Yet, everyone can use some help from time to time, and that’s what we’re here for. Contact us, and we’ll make sure you’re soaring through the sky in as soon as possible! We have all the parts for single and twin-engine planes you need.

MP50B-1 MOTOR ASSEMBLY – ANTI-SKID PUMP PACKAGE

MB38B-1 MOTOR ASSY – ACTUATOR

ES73175-4 BLOWER ASSY – FWD EVAPORATOR

ES73103-2 BLOWER ASSY – AC

1134104-1 MOTOR ASSY – COMPRESSOR DRIVE

130346-12 CONTROLLER ASSY – CABIN PRESSURIZATION

130346-11 CONTROLLER ASSY – CABIN PRESSURIZATION

100-555059-1 COMPRESSOR ASSY – AC

42113-005 PUMP ASSY – FUEL BOOST

How to Locate the Largest Inventory of Aircraft Parts

According to the aircraft owners and operators association(AOPA), 16 % of plane accidents between 1998 and 2003 were maintenance related.

Sourcing for aviation parts may not be a walk in the park as the government has licensed few businesses to sell them. finding the right seller sometimes proves to be hectic. Here are a few tips to consider when looking for an aircraft parts major vendor.

The Authenticity of the Products

In a world of fraudsters and greedy business practices, finding genuine aviation parts may not only save time and money but to an extent, even life. Non-genuine parts prove to fail from time to time. In aviation, this risk is too high to ignore. Authentic pilot supplies go a long way in ensuring your safety and that of your investment.

Fair pricing

The federal aviation administration insists on a maintenance check after every 100 hours of flight. It is, therefore, a costly affair due to its frequency. Getting spares at the right price is thus as important as getting the right supplier.

Customer Reviews

Customers reviews are important when dealing with a particular supplier. They may help you to judge their abilities and shortcomings. Sometimes, other customers may give information which is not readily available on request, such as credit facilities or after sales services.

Customer support

Support after a sale goes a long way in building a relationship between you as a plane owner and your supplier. Providing technical advice, loans and reservations are some of the ways a good supplier can help their customers.

Experience

A supplier will more likely deal with issues affecting their customers more if they have experienced in the sector. A lot of young businesses fail due to a lack of experience when they encounter problems. This means it will save you time when dealing with them.

Inventory

A supplier with a large inventory will save you time and indeed money when looking for pilot supplies. In many businesses, when a product is not available, they will still allow you to place the order then source for it from another supplier. This increases both its cost and the time needed to get it.

Ease of Access

A good vendor will have a website that is easy to maneuver. Although there are many suppliers available on the internet, one with a quality website is not as easy to come by.

As charity begins at home, the business should show quality from the word go, even online.

Compliance with Regulations

Regulatory compliance ensures that the suppliers in the industry adhere to set standards. This, in turn, protects the customers from business malpractices such as selling substandard products.

keep your fleet running by choosing the right aircraft parts vendor

Finding the right supplier of aircraft parts is paramount in keeping your aircraft in the sky. Choose the right vendor to save your time and money. Don’t hesitate to contact us for your maintenance needs and much more.

Air-conditioning-compressor-drive-motor-es61108-1

ES61107-1 MOTOR ASSEMBLY – AC COMPRESSOR DRIVE

0513120-8 VALVE ASSY – FUEL SELECTOR

2680234M1-13-VALVE-ASSY-FUEL-SELECTOR

1281033-1-ACCUMULATOR-ASSY-DOOR-CLOSE

23640-5-VALVE-ASSY-3-WAY-FUEL-SELECTOR

1233HNG284-PUMP-ASSY-HYDRAULIC

22A703-GENERATOR-ASSY-TACHOMETER

1H5-24-VALVE-ASSY-VACUUM-MANIFOLD

1H5-21-VALVE-ASSY-VACUUM-MANIFOLD

WTC2135-1 POWER PACK

4404-00-7NV-PUMP-ASSY—FUEL-BOOST

5033-2-VALVE-ASSY—FUEL-SELECTOR-

557-390 COMPRESSOR ASSY – AC

7088 COMPRESSOR ASSY – AC

EF210R-25212 COMPRESSOR ASSY – AC

F209R-16764-COMPRESSOR-ASSY—AC-

FQ4044-12021-INDICATOR ASSY DUAL FUEL QUANTITY

MB55B-1 MOTOR ASSY – AC CONDENSER BLOWER

MB56D-1 MOTOR ASSY – CONDENSER BLOWER

MB56D-1 MOTOR ASSY – CONDENSER BLOWER

How to Save Money On Piper Aircraft Parts and General Maintenance

While aircraft parts are expensive, they aren’t the only cost tugging at the budget of leaders across the industry. The International Air Transport Association (IATA) recently announced that airlines are also dealing with rises in fuel and labor costs as well.

As such, finding ways to save money without cutting quality or performance is now a critical initiative for professionals across the maintenance, repair and overhaul (MRO) field, including those working in an airline capacity.

Are you used to the reliability and sleekness that Piper aircraft parts afford? If so, you may be scratching your head wondering how to lower their price point.

The good news? There are plenty of ways to drive down the costs of these parts and their associated repair. You just have to know where to look. Today, we’re sharing a few ways to save money on aircraft parts, specifically the Piper ones you’ve come to rely upon and trust.

Ready to learn more? Let’s get started!

The Quality Behind Piper Aircraft Parts

There are many places you can afford to cut corners and cut coupons. You might opt for a generic brand toothpaste, or a bunch of bruised bananas at the grocery store, simply because they cost less than their counterparts.

While this tactic might work in the cosmetic or produce aisle, it won’t work on the tarmac.

Rather, aircraft carriers require top-of-the-line, high-performing materials to comprise their machines. Moreover, they also need trained and experienced laborers to install, integrate and maintain those components. That’s why Piper Aircraft Parts has distinguished itself as one of the most reputable brands in the industry.

In 1937, William T. Piper founded the Piper Aircraft Corporation. That same year, the Piper Cub made its debut. This lightweight aircraft featured an agile design and boasted some of the best low-speed handling capabilities of its time. Since then, the Piper name has become synonymous with innovation and progress within the aircraft industry.

In 2015, the Corporation unveiled its new “M-Class Line.” This was a series of three new aircraft: the M350, M500, and M600. In the years since, it’s remained a gold star standard in the aircraft parts arena. Piper also manufacturers some of the industry’s top hydraulic Power Pack solutions, available in both single engine and double engine designs.

Why Aircraft Costs are Rising

In a recent industry survey, MRO experts told interviewers that parts and labor prices were currently rising, expected to stay on an uptick into the foreseeable future. This means that operational expenses are also trending upward, putting a major strain on a niche that’s already pulled tight financially.

Some respondents cited that this escalation could be attributed to industry manufacturers attempting to claim intellectual property (IP). From engines to ground support equipment, there are myriad components to consider when designing and building an aircraft. Along the way, the higher the IP can be driven up, the larger the price tag manufacturers can demand.

At the same time that aircraft parts are becoming more expensive, so too is the labor required to work on them. Baby-boomer technicians, who used to be readily available, are now reaching retirement age. This leaves a major gap in skilled labor and makes it more difficult to find younger technicians interesting in learning the trade.

Thus, while Piper parts might have been more accessible only a decade ago, their in-demand status allows them to carry a higher dollar amount. Experts in a pinch who need a replacement part immediately might be tempted to go straight to the manufacturer and buy the equipment themselves.

Yet, with a little digging, you can often uncover opportunities to secure those parts for much less than you’d pay full-price. Let’s explore a few ways aircraft carrier organizations can find Piper materials and maintenance services at an affordable rate that makes everyone happy.

1. Start with a Parts Locating Company

Looking for to order a few Power Packs from Piper, but they’re backordered everywhere else you search? Do the prices you’re looking at make your head spin? Why not work with a company that takes care of the legwork (and the guesswork) for you?

A parts locating company works as its name implies. Once you know what kind of Piper equipment you need and how you plan to use it, a simple webpage search can yield you plenty of results, often for much less than you’d pay at the store.

This is an especially valuable service if you’re looking for rare or discontinued aircraft parts that might be required in some maintenance and repair situations.

It can also potentially save you millions of dollars in the long-run. How? You don’t have to pay any up-front capital expenses and holding costs often associated with building a parts inventory from scratch. You’ll visit the company on an as-needed basis and can expect quick delivery to ensure your operational needs are met and downtime is minimal.

Instead of worrying about fine-tuning your budget and saving every penny, handing over the reins to a parts locating company helps ensure that you’ll get the best deal around. This way, you don’t have to spend valuable time, energy and money on extensive cost comparison.

2. Find an Aircraft Parts Warehouse

In the retail sphere, shopping in a warehouse usually means sorting through cardboard boxes of unwanted or discarded items, usually available for pennies on the dollar.

While this can be a fun in-person exercise, it can also be time-consuming and before you know it, hours have passed and there’s definitely something in your cart you didn’t need.

Thankfully, aircraft experts don’t have to go through any of that. When you’re ready to see what’s available, you can visit an online aircraft parts warehouse to find even steeper discounts on already-low equipment prices. That means while you might find a Power Packs Plus solution for one price via a parts locating company, that same company may operate a virtual warehouse that has it for less.

The key here is to know your prices before walking in. It’s also helpful to know exactly how you intend to use the part before buying it. Remember the golden rule of salvage shopping: It isn’t a good deal if you don’t need it. Still, if you find what you need and want to check one more time to see if you can knock off some money, an online warehouse is worth a second look.

A Note on Buying Salvaged Aircraft Parts

Concerned that your salvaged Piper parts will over-deliver and under-perform? Worried that they won’t be as safe or reliable as their brand-new alternatives? Don’t be.

The airframe items available via these online warehouses must still pass rigorous testing procedures and compliance measures before being sold on the market. They will possess little to no total damage and if there is any present, it will be purely aesthetic and will not affect operations. In essence, they will be in optimal working condition.

Most major parts locating companies will have a warehouse division, either online or in-person. This allows them to better rotate their inventory and sell excessive items that lagged in sales on the full-time floor.

3. Consolidate Maintenance Shipping

Do you find that you’re always having to send separate shipments of aircraft equipment off to be repaired or maintained? Or, are you constantly ordering disparate pieces at the first signs of disrepair, then waiting by the door as a new piece arrives every so often?

If so, consider consolidating your shipments and deliveries to cut down on costs.

To do so will require taking a thorough audit of your current outgoing repair management tasks as well as any outstanding aircraft check projects. Then, see how you can join them in a strategic way that saves everyone time and money in the end.

While this may be a days-long undertaking, it’s worth it in the end. You’ll be able to more clearly see where you’re losing money on maintenance and shipping and how you can change a few plans around to conserve more overall.

4. Establish an Aircraft Maintenance Partner

Outsourcing your aircraft maintenance can allow you to breathe a little easier. Still, you might be tempted to only have a second set of eyes on your equipment when you spot a repair issue.

Across all industries, however, experts recommend keeping up-to-date on all routine and preventative maintenance care as well. Paying for this regular service now can set your fleet up for operational success down the road.

You may even be privy to repeat or long-term customer discounts. Depending on the level of service you require, most aircraft maintenance partners will manage your internal logistics as well.

Looking to save even more money? Talk to your aircraft maintenance partner about consolidating shop visits and inspections. Every second your aircraft is grounded, there is money being lost. To this end, it’s important to reduce downtime as much as possible.

Try to schedule maintenance visits and other planned tune-ups to occur at the same time so your aircraft can get back up in the air quicker. That might mean taking care of an oil change and a lubrication simultaneously, rather than scheduling those tasks at different times and landing the plane for each one.

5. Embrace New Technology

From 3-D printing to robotics and machine learning, there are many technological innovations that are changing the way aircraft leaders respond to and address technical issues. Forward-thinking aerospace leaders are those who embrace these new discoveries and look for ways to implement them back in the office.

As they do so, they can eventually allow machines to perform most of the simple maintenance tasks, freeing up a human laborer to focus on the more high-priority aircraft concerns. As such, maintenance costs are reduced.

This frees up your skilled technicians to focus on the troubleshooting issues that are the most important. As productivity improves, so too does the quality of work.

Take one industry example. An airline known as Air New Zealand is currently testing a robot that can climb walls and hold a camera. Originally designed to perform quality inspections on milk tanks, the robot is now being looked at as a viable and valuable solution for inspections and safety control experts in the airline field.

Though it takes some time to fine-tune these technologies, the cost savings benefits they offer could be substantial, especially as researchers and developers continue to perfect the technology.

Equipping and Maintaining Your Aircraft For Less

You want nothing but the best for your flyers, your crew and yourself. That’s why you installed Piper aircraft parts on your new plane or fleet of planes. Yet, you also need to be budget-conscious and conservative, especially during a time when industry prices are going up across the board.

Are you ready to find the aircraft parts you need at a price you can feel good about?

That’s where we come in.

We proudly offer a robust assortment of Power Packs designed to fit your aircraft. We also operate a salvage site that includes Piper in its inventory. That means you can finally stop calling around and opening up a dozen tabs on your browser. You’ll know the best price and service around are at your fingertips.

Still have a few lingering questions? Feel free to contact us today to learn more or to place an order.

EG5045-06017 INDICATOR ASSY, OIL TEMP, PRESS

C145-450 MOTOR ASSY, 24V ACTUATOR

1131325 COMPRESSOR ASSY, AC

42113-006-PUMP-ASSY,-FUEL-BOOST

9910157-5-RECEIVER-DRYER AC

5217-00-3-PUMP-ASSY,-FUEL-BOOST

2H22-11-VALVE-ASSY,-DEICE-RELIEF

1H24-18 VALVE ASSY, MANIFOLD

1H13-14 VALVE ASSY, FUEL SELECTOR, RH

1H13-13 VALVE ASSY, FUEL SELECTOR, LH

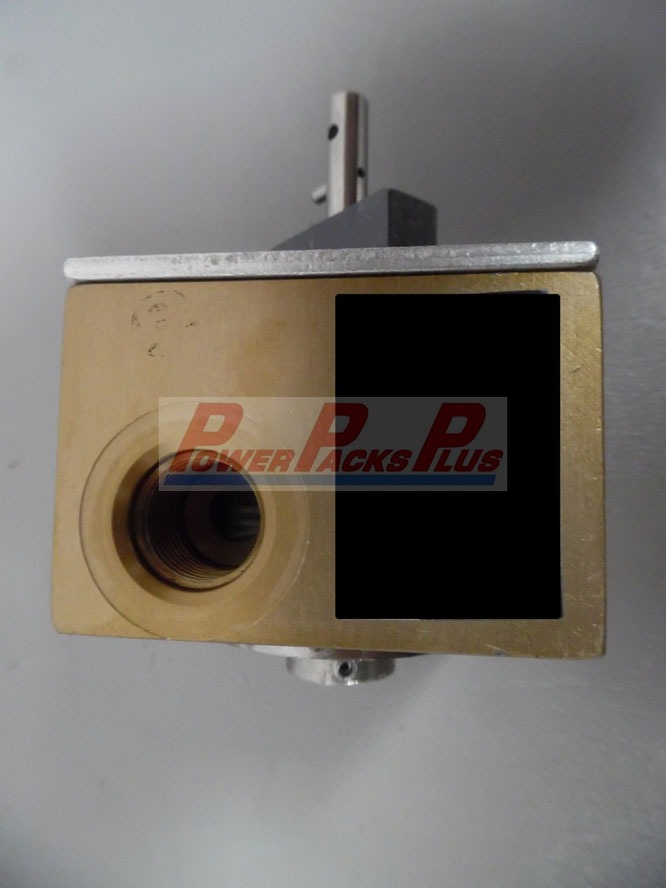

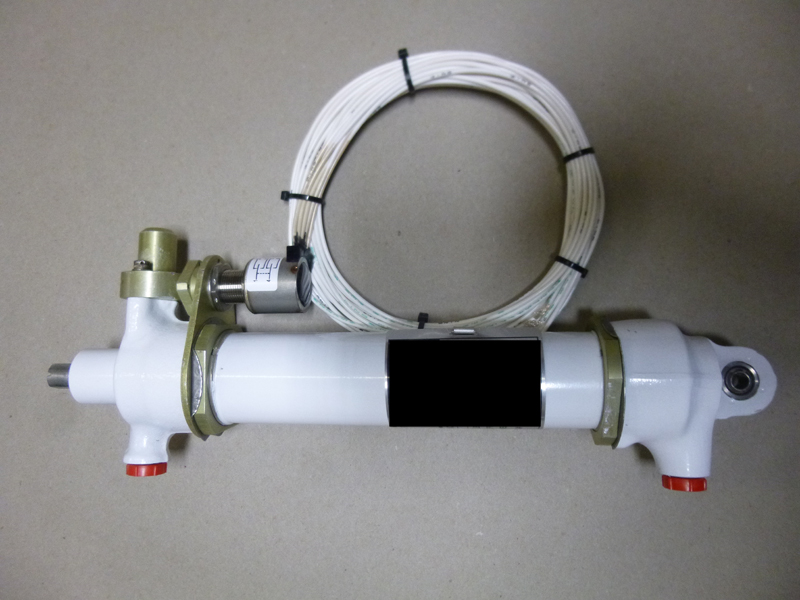

Everything You Need to Know About Hydraulic Power Pack Components

Figuring our hydraulic power packs for your aircraft can seem like a difficult task. The topic of hydraulic power packs is complex, technical, and wordy. Trust us, you are not alone!

But what happens when you need a replacement part for an airplane?

Understanding the purpose of hydraulic power and hydraulic power packs is tricky. That’s why we’re here to break it down for you into easy-to-understand terminology. We want you to feel confident you’ve chosen the correct source of power for all your machinery.

Airplanes can cost a lot to repair and replace. That’s why you’ll want to invest in only the best quality parts. This will keep you in the sky. It also ensures that your machinery runs well for years to come.

So, let’s delve right into it! We are going to break down the technical talk. Then, compile everything you need to know about hydraulic power pack components. But first, we got to know what hydraulic power is.

What Is Hydraulic Power?

Let’s start with the basics. Hydraulic power helps machines run better, faster, and stronger. In technical terms, it is a conversion. From a primary drive source to a pressurized hydraulic fluid flow.

You may be thinking: what difference does that make? It makes a world of difference for those that operate heavy machinery. Anything from airplanes to forklifts, for example.

Hydraulic power enables machines to work right. It also enables machine throughout a working day. The pressurized flow of fluid generates power. The power necessary to lift heavy weights, run tractors or trucks, and more!

Hydraulic power is closer than you think. In short, hydraulic power takes out the need for heavy-lifting and manual labor. So you can kick back, relax, and enjoy a little umbrella with your lemonade.

What Is a Hydraulic Power Pack?

We know now that hydraulic power is a source of power that helps with heavy lifting. In short, a hydraulic power pack is, in essence, a unit of booster power for machinery. They come in a variety of shapes as well as different sizes.

It may seem tricky when trying to pick one for your needs. Since power packs work inside many machines. Some can span up to the size of a car. While others are comparable to the size of your everyday hurricane generator.

Needless to say, there are a variety of options to choose from. Each serves a different purpose to get the job done. Now…some hydraulic power pack units remain stationary. That means these are not for transporting from one location to another.

Others are smaller and more compact. These can sustain movement and transportation. You can take them from one location to another to complete many jobs.

So…How Does It Work?

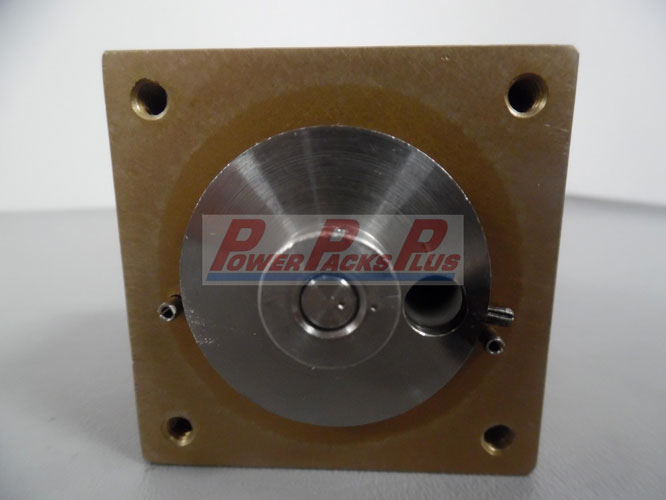

We’re so glad you asked! The hydraulic power pack works as a team transferring and converting power. We’ll learn about electrical, mechanical, and hydraulic. But first, we have to examine each major piece alone to get a better understanding.

The most important factors of a hydraulic power pack are the components inside of it. Hydraulic power packs work by a series of components that allow it’s function.

The unloading valves of a hydraulic power pack are:

- Motor

- Hydraulic pump

- Hydraulic reservoir

- Regulators

- Pressure supply and relief lines

Components and Their Functions

We can’t understand a hydraulic power pack without dissecting its components. We’re going to list off each major component, and then their functions.

As we do this, we can ask ourselves these simple questions:

- What do these parts do in the grand scheme (bigger picture)?

- How does it all come together?

Let’s dive a little deeper and see the purpose behind hydraulic systems components.

Motor

The first component is the motor. The motor is your primary source of power. Like we mentioned earlier, the primary source or the motor (electric power) converts.

That means that the primary source, or the motor, turns into mechanical. Later on, we’ll find out how it converts into hydraulic power. The primary source controls oil dispersion.

So then, the primary source could the one that controls the pressure supply or fluid flow. If we want to be technical, the motor handles converting. Either DC motors and AC motors (primary sources) from electrical power to mechanical.

By all means, you’ll want your hydraulic power pack born wild…get your motor running, headin’ on the highway…explode into space (no pun intended)…

Yet, with all the motors mighty power, it’s useless without a hydraulic pump. Which leads us to our next component and its function.

Hydraulic Pump

Its nickname is the “heart” of the hydraulic power pack. The hydraulic pump controls flow and pressure. More exactly, the flow and pressure of the fluid within a unit.

Here’s where that one question comes into play. How does the motor turn mechanical power to hydraulic power? The answer is: the pump.

The motor converts electric power to mechanical. Then, the hydraulic pump takes the mechanical power and makes hydraulic pressure.

In simple terms, the pump works to balance the ratio of the area within the unit and pressure. You should note there are unloading valves of hydraulic pumps. Some include: gear pumps, vane pumps, and piston pumps.

Hydraulic Reservoir

Another vital hydraulic component is the unit’s reservoir. This is the storage area for the oil. The oil then flows and passes through the reservoir into the hydraulic pump. The oil pumps through the entire system and back again. Then, the cycle repeats.

The oil keeps other components running like the motor. Maintaining your oil clean and pristine is super important. Dirty oil can clog the functions within the unit and cause many issues.

You’ll want to do unloading valves on your unit. Check that the oil is clean! That means no dirt, dust, or other contaminants.

Keeping the oil clean will keep your power pack operating smoothing. It’ll ensure that all fluids flow easily without damaging your equipment. Specific strainers and filters will keep out unwanted material.

Pressurized and Non-Pressurized

This is worth mentioning as well. Airplanes that are cutting corners fast or making sharp turns will have pressurized reservoirs. Commercial airplanes like an ordinary flight from JFK to LAX will most likely be non-pressurized.

The main reason for this has to do with temperature. unloading valves can rise fast in hydraulic systems. That’s why mechanical engineers invest countless hours to produce mature technology.

That is mature technology which will give the power needed to complete a task at hand. And do so without overheating.

Fins

We all know that liquids change when they’re put inside an airplane and pressurized. That’s why TSA takes away our favorite shampoo to throw it into the bin before we board. But, what happens to the fluids inside a reservoir when a plane is in flight?

Liquid moves in flight. It’s going to whirl and twirl, so we have to get ahead of the game and prepare for that. That’s why we have a little something called fins. Fins work to prevent movement that could disrupt the system.

Fins go inside of the hydraulic reservoir. There are, in general, many fins alongside either wall of the reservoir to break up bubbles. Fins keep the fluid from swirling, twirling, and tangling into a bubbly mess.

In short, it keeps the fluid stabilized. This keeps the power pack circulating and avoid clogs or disruptions in the system.

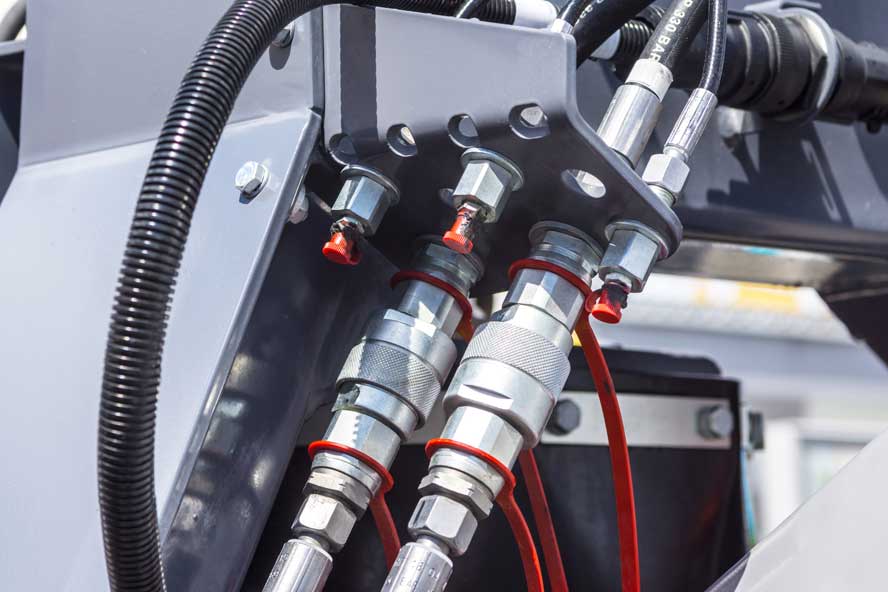

Regulators

Hydraulic power pack regulators control or “regulate” the pressure lines. These regulators work to keep your system from becoming over-pressurized. Regulators are also called unloading valves.

Pressure control valves are what power the power pack. There are also the directional control valves. These work to regulate the oil amount flowing throughout the system.

Different valves keep pressures set within range. This ensures that you have better control over the fluids, pressure, and power pack.

Pressure Supply and Relief Lines

Pressure supply and relief lines keep the pressure inside the pack leveled. We know that the pressure inside the pack is set by the control valves. This means that the pressure will also be the same when in the supply and relief lines.

In other words, the pressure supply and relief lines pump the fluids at a set pressure. The pressure is set using the control valves. These lines ensure that the fluid cycles.

The pressure keeps air bubbles from manifesting inside. It keeps the fluids pure inside the tubing. That is the same purpose as the fin design that’s inside the hydraulic reservoir.

Maintenance: Yay or nay?

This is a definite yay or yes!

Maintenance is crucial for the long-lasting survival of any piece of equipment. Keeping a hydraulic power pack maintained keeps it thriving. The most vital part of keeping a power pack clean, again, is the oil inside the hydraulic reservoir.

Keeping the oil clean should be a top priority. Don’t worry, there’s accessory equipment that can help you keep out contaminants. Installed filters and strainers inside that’ll collect contaminates as the fluids cycle through.

Still, it’s important that you check up on the oil inside of the reservoir to be sure it is clean. Handling the oil the right way, from the start, avoids damaging the reservoir. It also avoids damage to other functions in the long run.

How About Airplanes?

Now that we know about hydraulic power and power packs, we can see how it all ties into airplanes. Pull up a chair! This is going to be the best part.

Most airplanes have hydraulic systems for their craft in case of an emergency. These extra sources of power help when the main systems fail. Older and newer airplanes will differ in how their systems makeup. Yet, the differences are minimal and they are inside the hydraulic reservoir.

Older models there is an extra valve to allow the passage of filtered oil in case the first one has damage like a clog. That’s only the tip of the iceberg, though. Let’s dig even deeper into what hydraulic power packs do for airplanes.

How Is a Hydraulic Power Pack Used in an Airplane?

Hydraulic power systems became popular for larger airplanes. That’s because pilot’s couldn’t manually operate flight controls anymore. They needed an extra boost. Smaller airplanes could. Still, in commercial planes, for example, the pilot needed an extra boost of power. Hence, the hydraulic power pack system.

You may be wondering: how does this hydraulic power boost help pilots?

Here are some ways hydraulic power benefits pilot’s in large, commercial airplanes:

- Stabilizer trim

- unloading valves

- Flight control surfaces [directly]

Hydraulic power pack components enable large commercial planes to function better. Large airplanes are able to get away with not having to install a central hydraulic system. Power packs make the job easier and lighter to travel.

Here’s How It All Ties In

These listed hydraulic components and functions work together in a: hydraulic system circuit. These hydraulic power packs embody innovation. The use of valves, filters, and compact lineage is what makes these power packs so creative.

These packs are essential for any plane. Because they lessen the weight which free’s up space. That’s why we offer them to our customers!

Take Your Pick from Our List of Hydraulic Power Packs

Choosing the right products for your airplane can seem daunting or even frightening. It does seem like a lot of information, but we’re here to help. After all, we all want the best for our airplane.

That’s why we would like to invite you to check out our many airplane products. Take your pick from our list of various hydraulic power packs. We strive to bring you the sturdiest materials that’ll work great with your airplane.

Soar through the sky in style, knowing you’ve invested in the highest quality products. If you’ve been searching for a hydraulic pump, then look no further because we’ve got you covered. We offer our customers many more options in aircraft parts, so feel free to surf our inventory.

RG17980UM PUMP ASSY – ENGINE DRIVEN FUEL

To request additional information or to place an order please call us at Phone 775-322-8555, Or by faxing us at Fax 775-322-8562.

You can also complete the inquiry form below.

WTC2115-1 ACTUATOR ASSY LANDING GEAR

SFA232-5 ACTUATOR ASSY LANDING GEAR

FQ4026-12020 INDICATOR ASSY DUAL FUEL QUANTITY

FQ4026-12020- INDICATOR ASSY DUAL FUEL QUANTITY

9881141-1-MOTOR-ASSY HYDRAULIC POWER PACK

83903 COMPRESSOR ASSY AC

475-194-MOTOR ASSY FLAP & ICE DOOR 24 V

Aircraft Parts Availability

475-194 MOTOR ASSY FLAP & ICE DOOR 24-V

1H37-1 VALVE ASSY CHECK

1H26-4 VALVE ASSY FUEL-SELECTOR

Aircraft Parts

OEM or PMA Aircraft Parts: What’s the Difference?

Last year on July 20th, there were 54,150 flights crisscrossing the United States. This was the busiest day of the year for the FAA.

The FAA regulates more than the aircraft in the air. They also regulate the aircraft engine parts and production that goes into them.

There has long been a debate over whether you should buy OEM or PMA parts. This is partly because of no longer relevant beliefs about the safety of PMA parts.

We are going to set the record straight on their price, quality, and regulation.

Certifications Given to Aircraft Parts

The FAR Part 21 regulates the production of airplane components. There are a few different types of approval a part is eligible for.

PMA Aircraft Parts

Parts manufacturers get a PMA certificate to produce aircraft parts that they are not the original manufacturer. This is like aftermarket parts manufacturers in the auto industry.

The FAA regulates who can produce parts. A manufacturer must apply to the FAA for approval. There are three methods that can give PMA certification.

Identicality

For this method, the manufacturer applies to the FAA showing their part is identical to the OEM part. The easiest way to prove identicality is through licensure.

The manufacturer will show that they licensed the part from the OEM. Sometimes the OEM will provide documentation confirming this.

Test & Computation

This method uses general and comparative analysis. The general analysis compares the functional needs of the new part to the original one.

The comparative analysis looks at the functioning of the part as compared to the original one. The FAA Aircraft Certification Office (ACO) performs the tests. A determination of compliance is then issued.

Production Approval

A PMA meaning is not complete without the product approval process. Once the part gets determined as identical, it needs to pass production approval.

This approval comes from the FAA Manufacturing Inspection Divisional Office (MIDO). This part of the process checks the manufacturing process. Only complying parts should make it to the marketplace.

A company with Production Approval Holder (PAH) already has production approval before applying for PMA. PAH approval goes to the manufacturer while PMA approval is for parts.

Identifying a PMA Part

Each PMA part produced by a PAH must have “FAA-PMA” stamped on it. The PMA must also include their name, trademark, and FAA ID and part number.

All markings need to have some sort of permanency. The best practices have this information stamped into the part.

If the part is too small to have a mark then an attached tag will have the information. If this is still impractical, the tag can refer to a manual or database for reference.

OEM Aircraft Parts

OEM stands for Original Equipment Manufacturer. These are like the OEM parts that auto manufacturers produce.

At the beginning of aviation, OEM aircraft parts were the only option. This was because the manufacturer made the plane, so they had the ability to make the parts.

Type Certificate

The holder of a type certificate is the OEM. Only OEMs can produce parts under this certificate.

The certification for the part is easier under this certification. It references the OEM’s application of airworthiness for the aircraft. Since the OEM proved the part was safe in the approval of the overall craft.

Production Type Certificate

Any manufacturer with this certificate can produce a part with FAA approval. The approval lasts for up to 6 months after issuance. This requires the FAA to regulate the manufacturer for assurance of compliance.

Technical Standard Order

The FAA issues a Technical Standard Order or TSO. It is a regulation for the minimum performance standards.

These apply to parts, materials, and appliances on civil aircraft. These written orders will outline the parameters for input, output, and operating.

Any other minimum operating requirements are also included. TSOs get issued publicly.

This aids the FAA in developing a uniform standard of performance. The FAA makes issued TSOs available on their website.

Technical Standard Order Approval

An often confused acronym is TSOA, which stands for Technical Standard Order Authorizations. This is when the FAA gives their approval to produce a part or material.

When a part receives approval, it is for both design and production. To receive this approval, a manufacturer must show two things in their application.

They must show that the design of the part meets the TSO minimum standards. They also need to prove there is a manufacturing system in place. This ensures each part produced meets minimum standards.

No Installation Authority

The difference between PMA and TSOA is that the TSOA does not give installation approval. A PMA gives installation approval for a specific aircraft.

A TSOA gives minimum standards of performance in a wide variety of aircraft. The FAA gives approval based on whether the part is a minor or major change to the aircraft.

The Price Difference

It is a common misconception that items that are more expensive must be of better quality. This way of thinking is not limited to the aircraft industry.

Go to a mall or grocery store and you’ll see people choosing name brand products. They think these brands are better quality than their off-brand alternatives.

In other industries, there is debate over which ones are better. The has worked hard to make this a non-issue for the aviation industry.

The FAA holds all parts to the same quality and safety standards. This means that the part will perform as expected no matter what you’ve paid for it.